Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Treadmill Magnetic Tiles Improve Motor Reliability

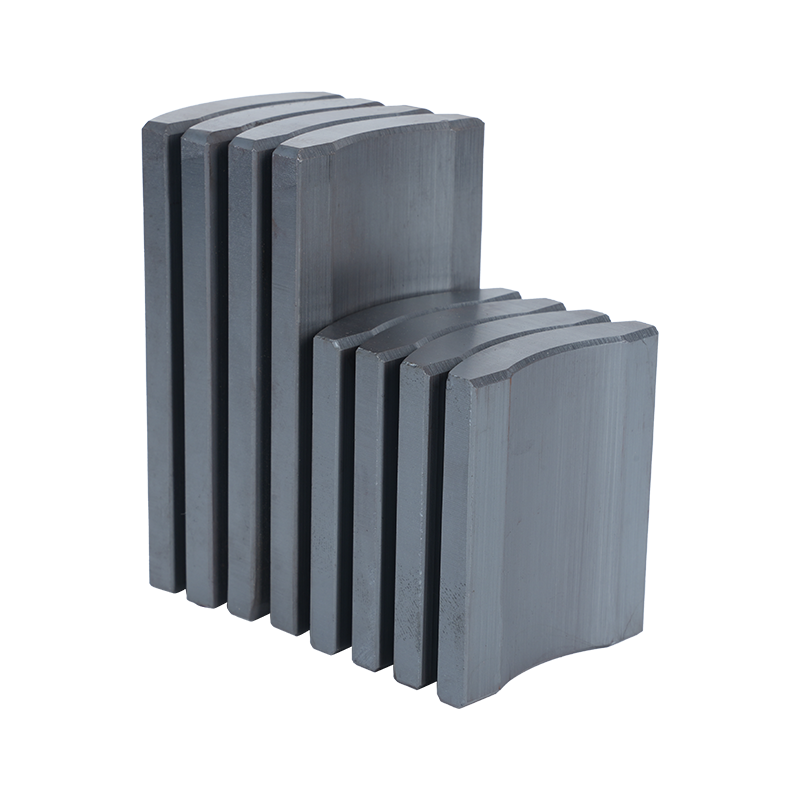

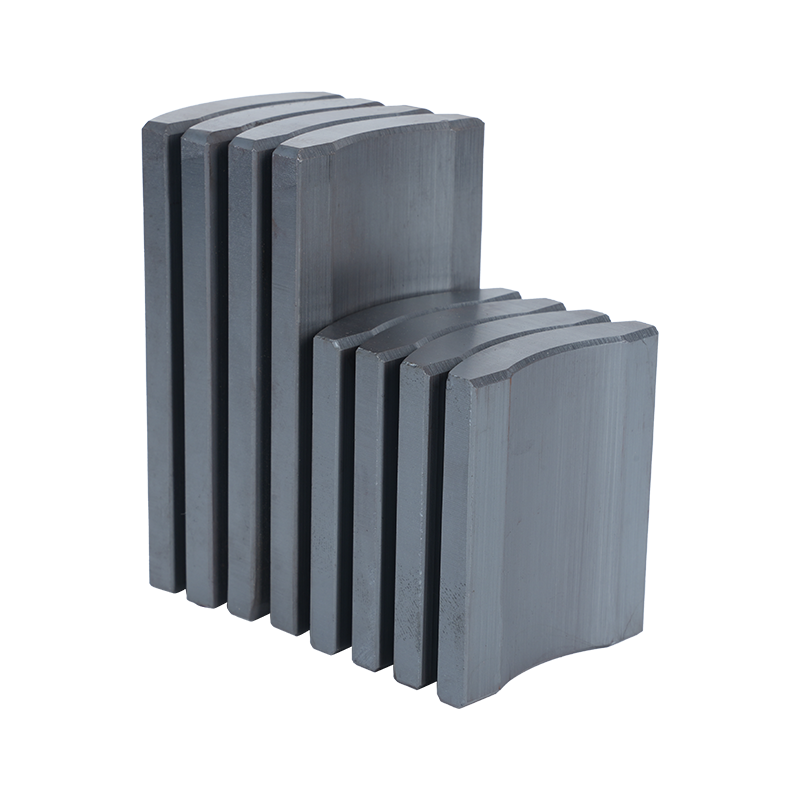

The term treadmill magnetic tiles refers to engineered magnetic arc segments used inside treadmill motors to shape magnetic flux, stabilize rotation, and support sustained performance. As demand for quieter, longer-running treadmills grows in gyms, rehabilitation centers, and home fitness settings, magnetic tiles are appearing more often in technical conversations about motor design and maintenance.

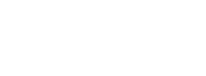

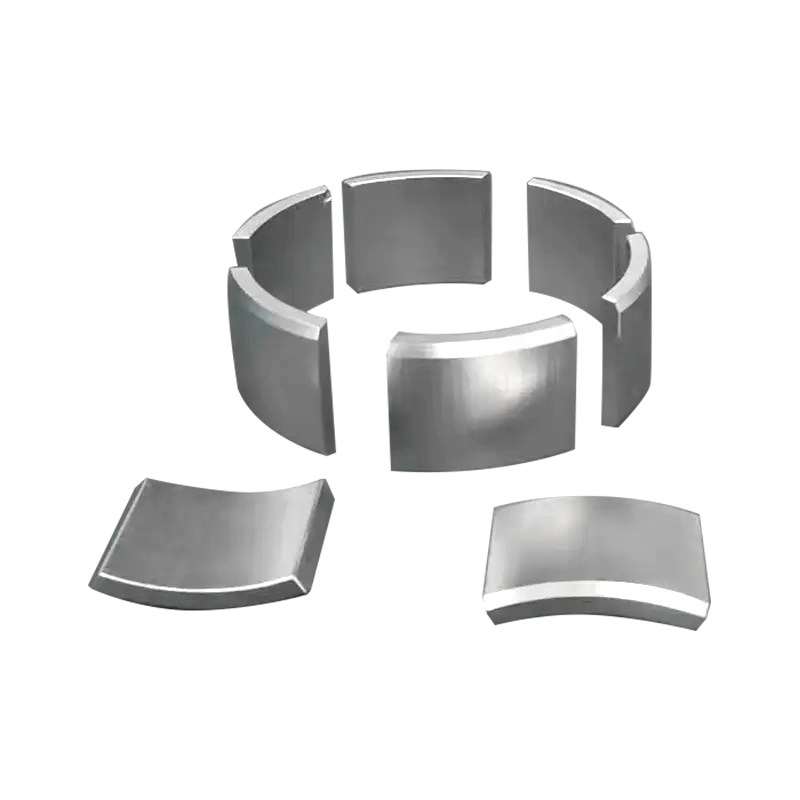

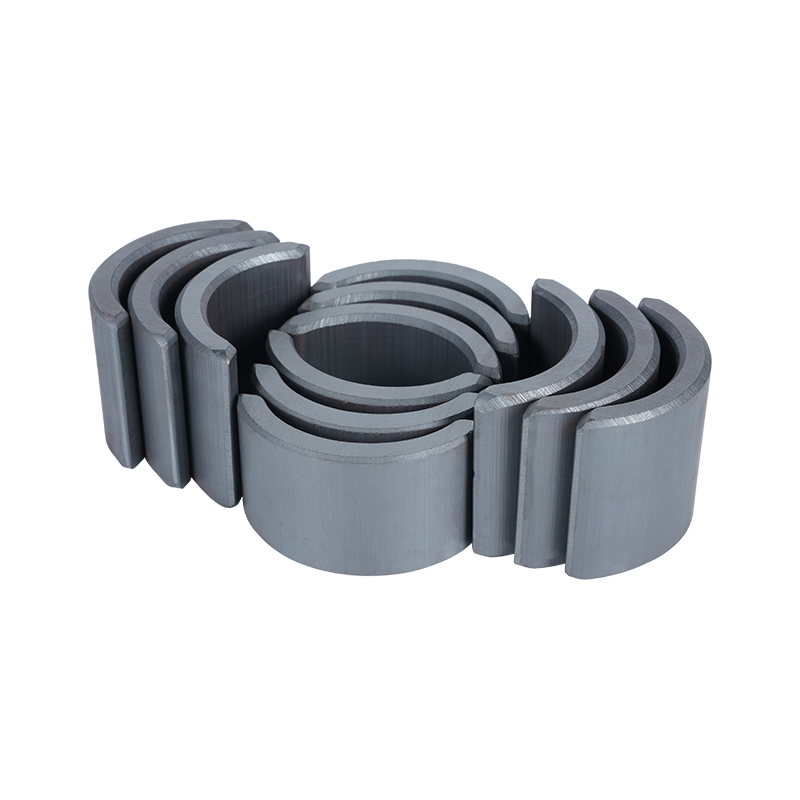

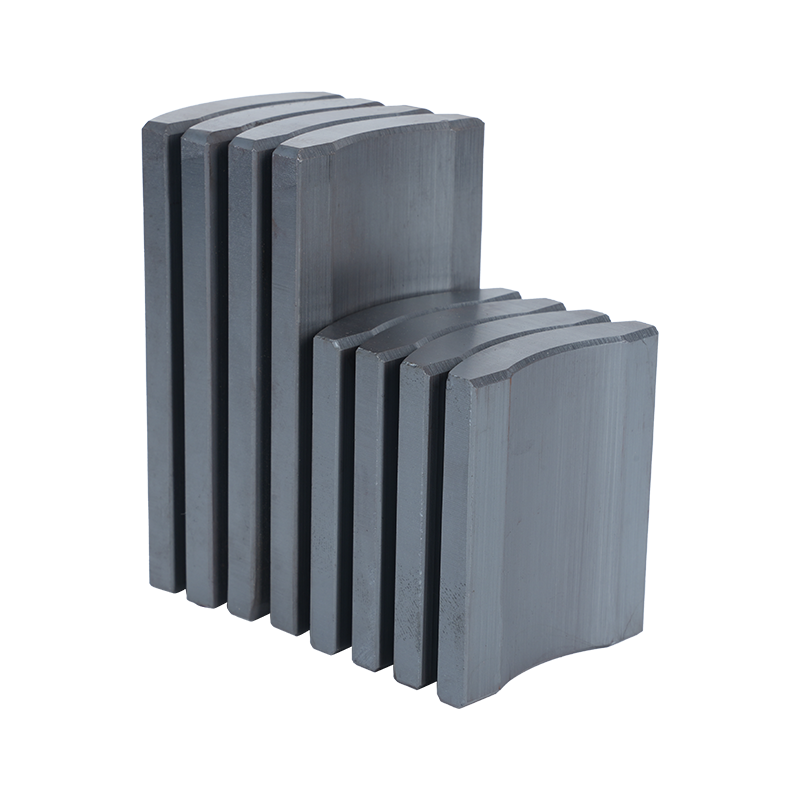

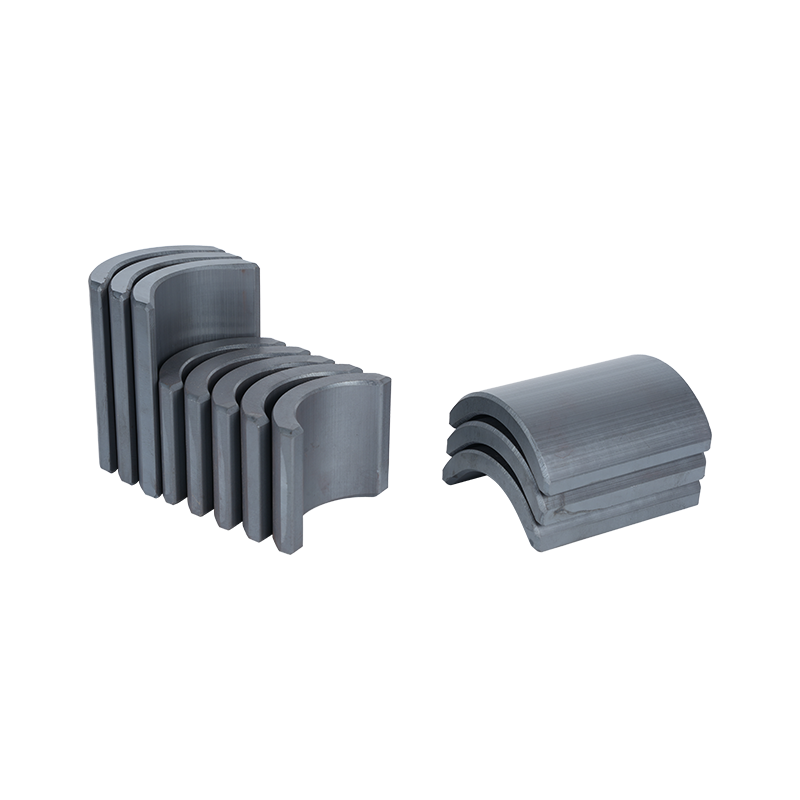

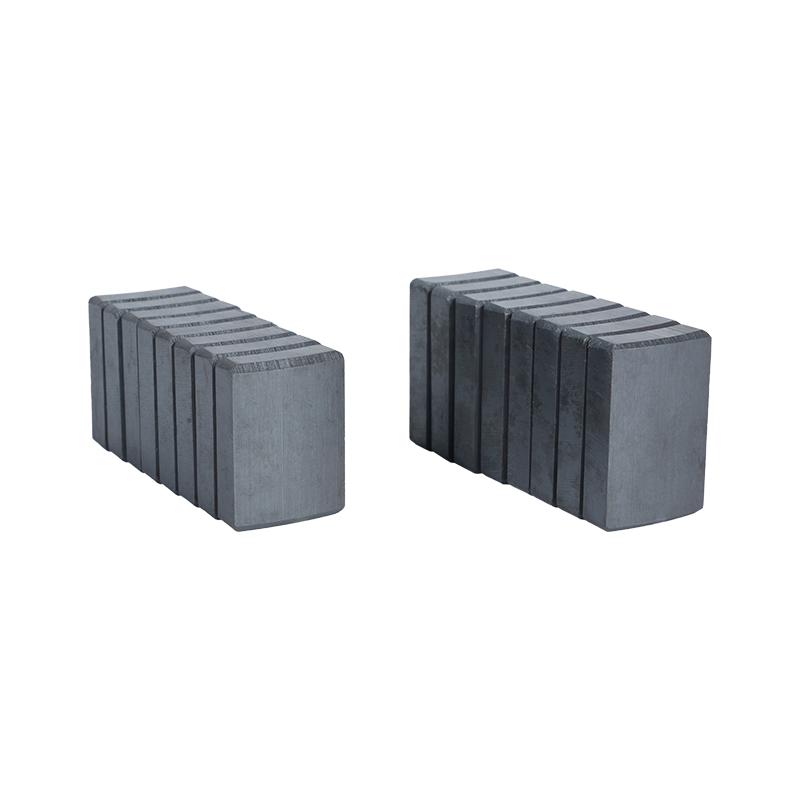

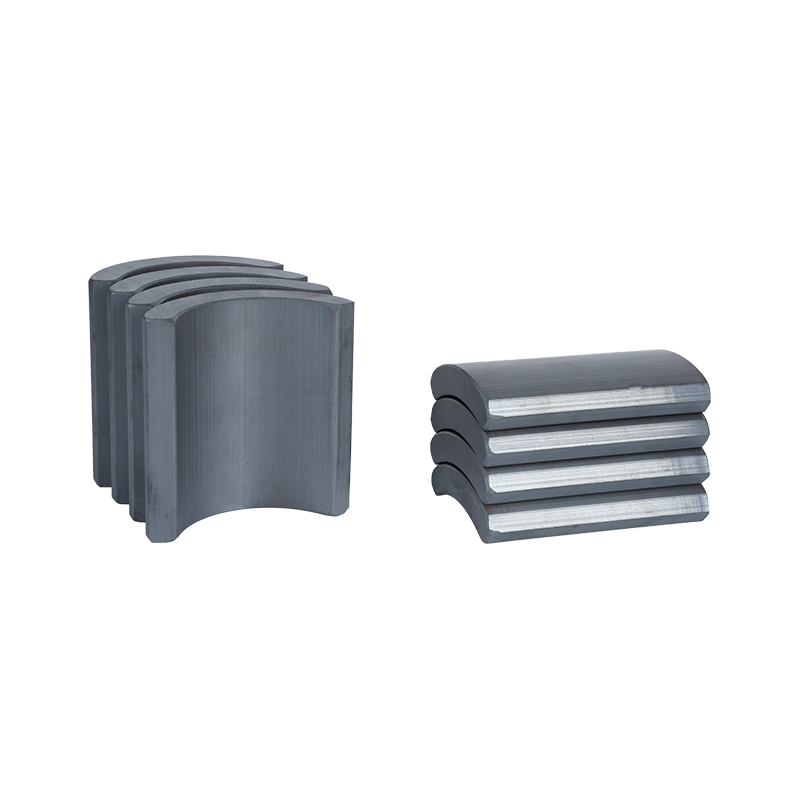

Magnetic tiles for treadmill applications are typically made from ferrite or sintered ceramic materials and formed into curved segments that match the rotor geometry. Their core functions include uniform magnetic field distribution, thermal stability under continuous duty cycles, and simplified repairability through segmented replacement. Engineers note that selecting appropriate arc angle, thickness, and magnetization direction helps tailor motor behavior for specific treadmill models and load profiles.

Key technical and commercial themes include:

- Motor stability: segmented tiles reduce uneven magnetic pull and lower vibration levels during high-speed or incline operation.

- Thermal tolerance: ferrite tiles keep magnetic properties stable at elevated operating temperatures common in continuous treadmill use.

- Customization: manufacturers provide arc size, grade, and coating options to meet varied motor housings and environmental conditions.

- Serviceability: segmented designs enable replacing a damaged tile rather than reworking the entire rotor, shortening service time.

Practical application data observed by machine builders and facility operators often focuses on run time, maintenance intervals, and noise reduction. Typical observations include:

- Average continuous operating windows of 4–8 hours per day in commercial settings without notable magnetic degradation.

- Measured vibration reductions of a noticeable percentage when segmented tiles replace older non-segmented magnets.

- Lowered incidence of torque fluctuation during sudden speed or incline changes.

- Easier field repairs when a single tile can be swapped instead of replacing full assemblies.

Manufacturers also emphasize production methods such as precision sintering and magnetization control. These steps help ensure consistent magnetic strength across batches and maintain concentric flux patterns that the motor design assumes. Coatings and adhesive bonding techniques are used to protect tiles from mechanical shock, moisture, and chemical exposure encountered in some gym and industrial environments.

For product designers, tradeoffs are common: ferrite tiles are valued for thermal stability and cost efficiency, while higher-grade earth options may offer stronger magnetic intensity for compact, high-power designs. The decision typically balances cost, target torque, and expected duty cycle. In many treadmill models where predictable, smooth motion and low noise are priorities, properly sized ferrite tiles deliver a functional compromise between performance and price.

Facility managers evaluating replacement parts or new treadmill purchases can use a short checklist to assess motor magnetic tile suitability:

- Confirm tile material (ferrite, ceramic, or earth) and rated operating temperature.

- Check arc geometry and fit with the existing rotor assembly.

- Ask about coating and bonding methods that resist vibration and moisture.

- Request sample performance data under duty cycles representative of your use case.

- Verify availability of spare tiles for efficient field service.

Beyond technical considerations, suppliers report growing interest from OEMs that aim to design lighter treadmill frames and quieter drive trains. Modular magnetic tiles allow motor form factors to be rethought, freeing design space for slimmer consoles and improved cooling channels.

If you manage a fitness facility, design treadmill hardware, or source motor components, inquiries into tile grade, customization options, and make times can help align procurement with operational goals.

In closing, treadmill magnetic tiles are a practical motor component that can influence noise levels, torque stability, and serviceability in modern treadmill designs. If you would like technical specifications, sample testing options, or pricing for specific tile geometries, please reach out to discuss your requirements.