Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Cleaning Machine Magnetic Tiles Selection Guide

Cleaning machine magnetic tiles are critical components for motors used in industrial floor scrubbers, commercial sweepers, and automatic cleaning machines. Proper selection and maintenance of these tiles can directly affect motor efficiency, operational stability, and overall machine reliability. Understanding the materials, geometry, and installation methods is essential for manufacturers, maintenance teams, and procurement specialists seeking long-term operational consistency.

Function and Role in Cleaning Machines

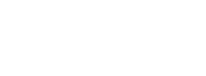

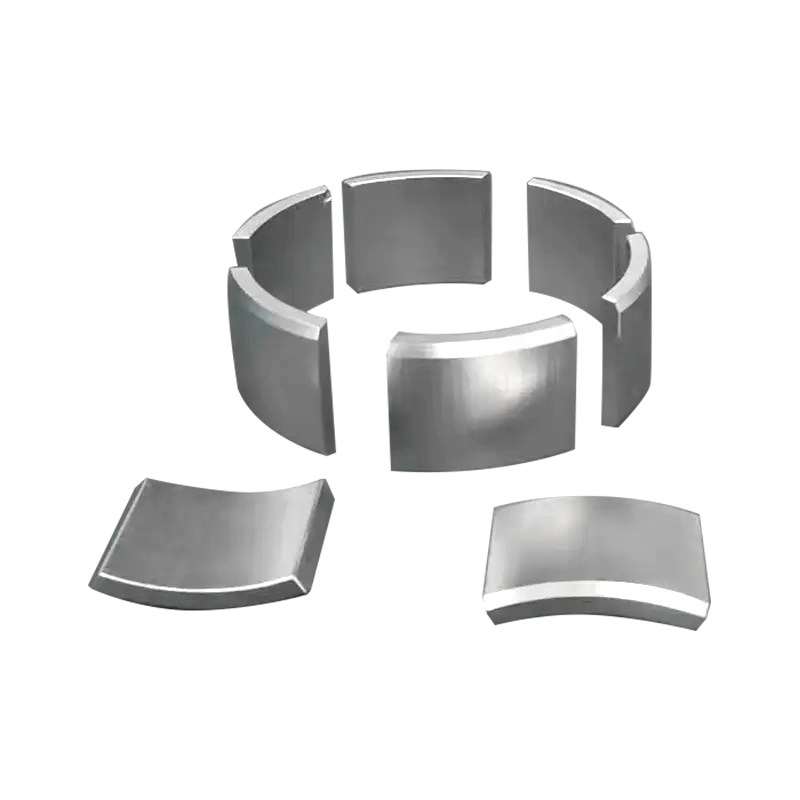

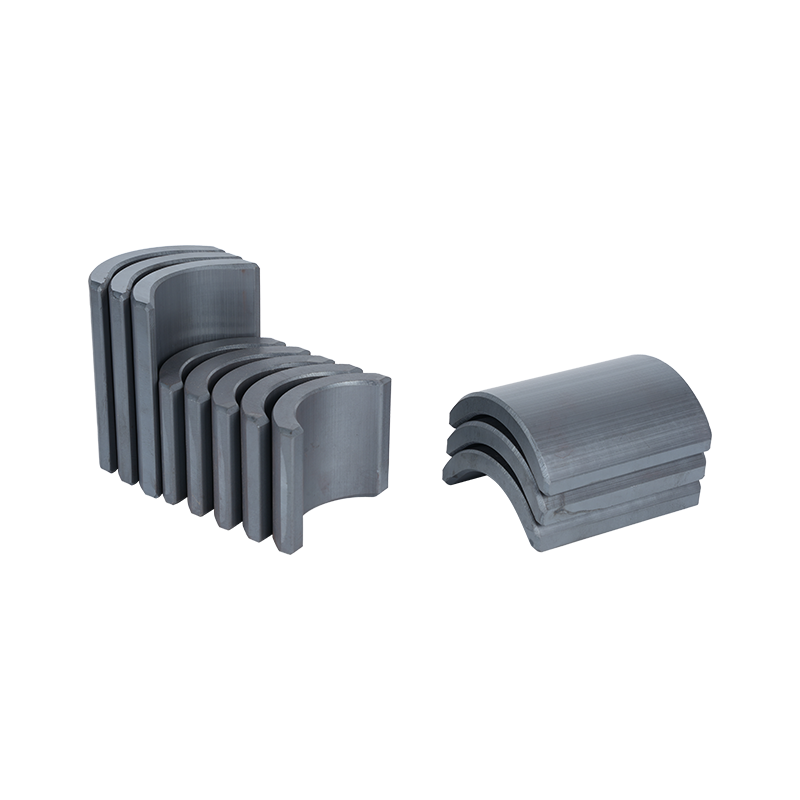

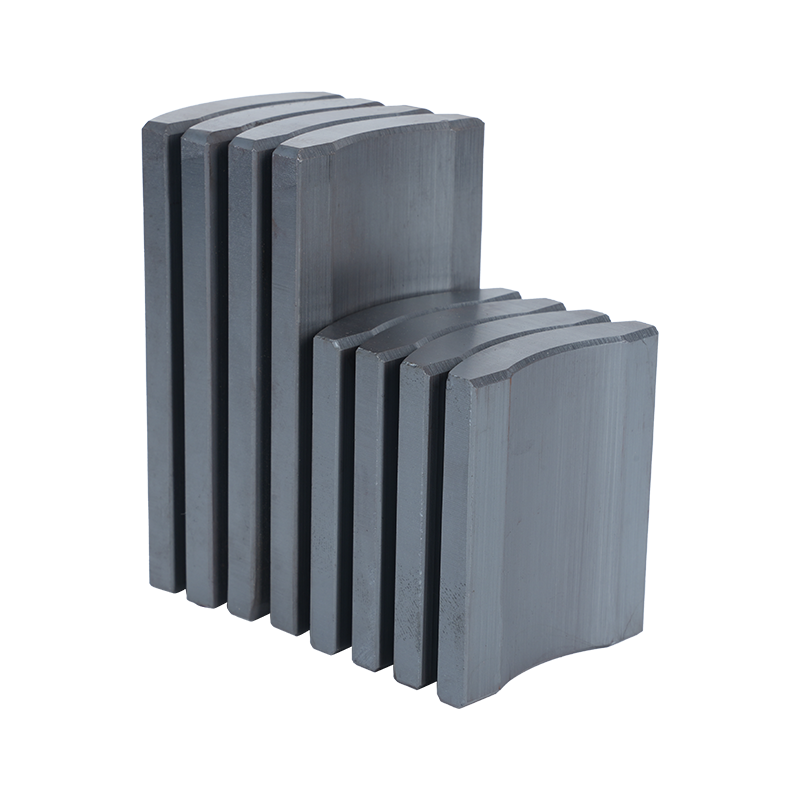

Magnetic tiles are segmented, arc-shaped magnets mounted on the rotor of a cleaning machine motor. They provide a stable and uniform magnetic field that ensures:

- Consistent torque output under varying load conditions

- Reduced motor vibration and operational noise

- Smooth rotation, particularly in machines operating for multiple hours continuously

- Efficient energy usage, minimizing current spikes and overheating

In industrial and commercial cleaning machines, such as floor scrubbers and autonomous cleaning robots, magnetic tiles play a central role in maintaining consistent brush and roller motion, which directly impacts cleaning performance and surface protection.

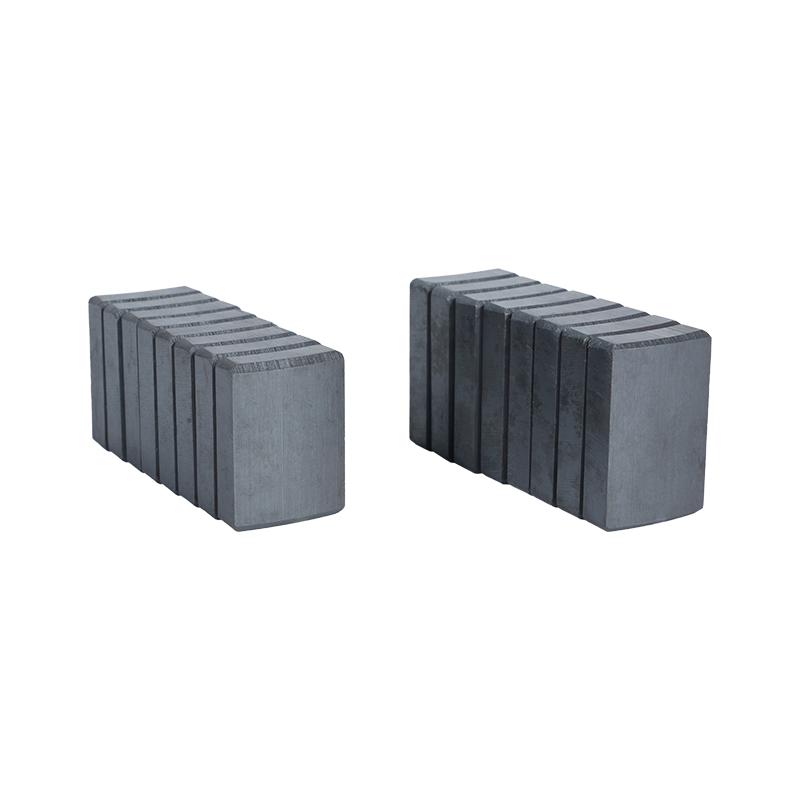

Material Considerations

Choosing the correct material is essential for performance:

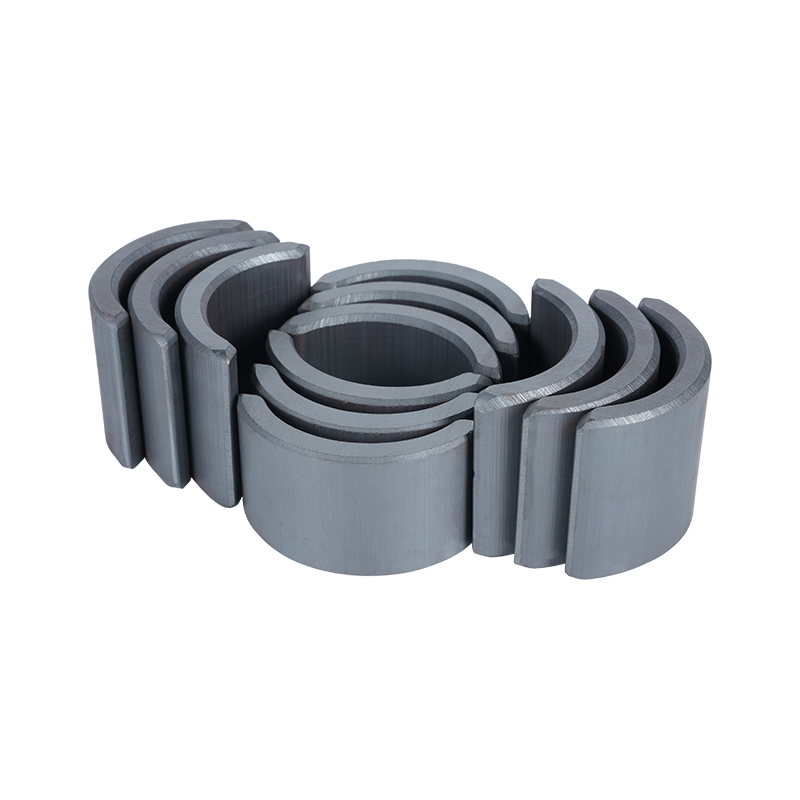

- Ferrite Tiles: Offer thermal stability, resistance to demagnetization, and cost efficiency. They maintain performance in high-duty cycles, such as cleaning large warehouses or hospitals.

- Ceramic Tiles: Provide higher dimensional precision and uniform magnetic alignment, suitable for compact, high-speed motor designs.

- Protective coatings: These safeguard the tiles from moisture, cleaning solutions, and mechanical wear. Coated tiles resist corrosion and extend service life.

Material selection should also consider the operating environment. Facilities with high humidity, chemical exposure, or continuous operation may require tiles with enhanced thermal tolerance or specialized coatings.

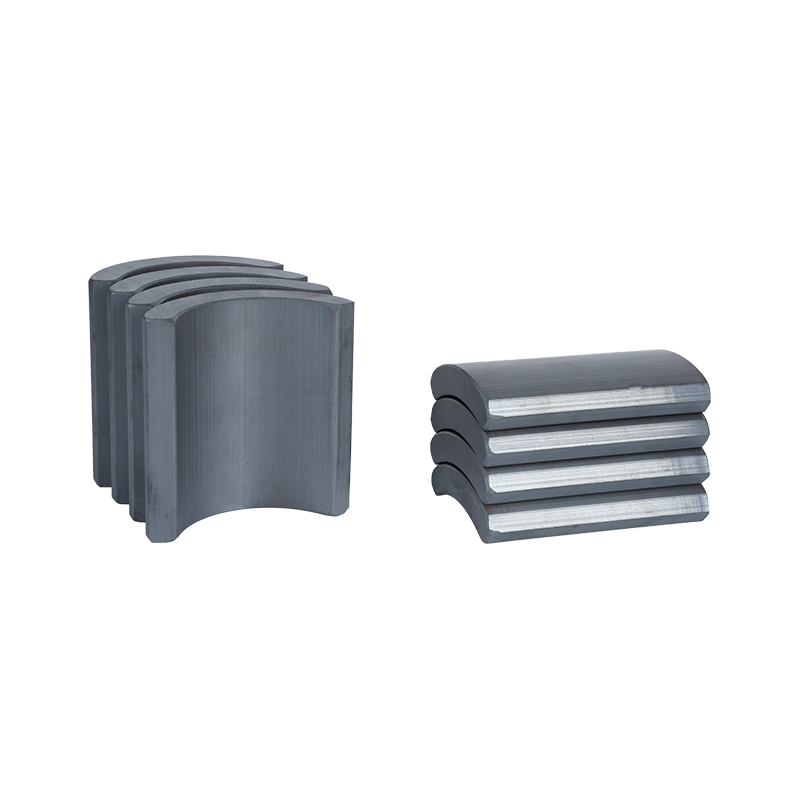

Tile Geometry and Installation

Proper sizing and alignment of magnetic tiles are crucial:

- Arc length and thickness: Must match the rotor design to prevent uneven magnetic pull and vibration.

- Magnetization direction: Correct orientation ensures uniform flux distribution and stable rotational speed.

- Segmented design: Allows replacement of individual tiles without disassembling the entire rotor, reducing maintenance downtime and service costs.

Industrial operators note that precise alignment prevents torque fluctuation, minimizes energy loss, and improves operational stability, particularly in machines running on variable floor surfaces.

Maintenance Practices

Routine inspection and maintenance of magnetic tiles can prevent operational issues:

- Check for cracks, chips, or misalignment regularly.

- Inspect magnetic strength periodically to ensure consistent torque.

- Replace individual segments as needed, which avoids full rotor replacement.

Well-maintained magnetic tiles help reduce motor wear, extend component life, and maintain the efficiency of cleaning operations over time.

Performance Observations

Data from industrial use and field feedback suggest:

- Motors with ferrite tiles operate continuously for 5–8 hours per day without significant performance loss.

- Machines using segmented magnetic tiles show lower vibration and smoother brush or belt movement.

- Torque output remains stable during sudden changes in load, such as inclines or uneven floors.

- Energy consumption is more predictable, reducing overall operational costs in large facilities.

Such characteristics are particularly valuable for cleaning machines deployed in high-traffic areas like warehouses, hospitals, airports, and logistics centers.

Procurement and Selection Checklist

When sourcing cleaning machine magnetic tiles, consider:

- Compatibility with the motor rotor dimensions

- Material grade and thermal tolerance

- Tile arc length, thickness, and magnetization direction

- Availability of spare tiles for maintenance

- Protective coatings and bonding methods for durability

Suppliers often provide technical drawings and sample tiles for testing to ensure the selected components meet operational requirements. Customization is common to fit specific motor designs or application needs.

Conclusion

Cleaning machine magnetic tiles are essential for maintaining reliable motor performance, stable torque, and consistent cleaning efficiency in industrial and commercial machines. Correct material selection, precise installation, and regular maintenance ensure long-term operational stability and minimize downtime. For manufacturers and facility managers, understanding the technical specifications and replacement strategy is key to maintaining machine performance. Suppliers can provide detailed specifications, sample tiles, and technical support to meet diverse operational needs.