Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Ferrite Magnet Use Expands in Industrial Motors

In recent years, permanent magnetic ferrite materials have drawn increasing attention in sectors using electric motors, from cleaning machines to small industrial devices. Their combination of cost‑effectiveness, thermal stability, and magnetic retention makes them a frequent choice when designing motors requiring durability and long service life.

Why Engineers Choose Ferrite Magnets

Permanent magnetic ferrite magnets offer several advantages that meet the demands of industrial motors:

- Thermal tolerance: Ferrite materials hold magnetic properties even under elevated temperatures common in continuous operation, reducing risk of demagnetization.

- Corrosion resistance: Properly coated ferrite magnets resist moisture and chemical exposure, ensuring longevity even in damp or harsh environments (e.g., cleaning machines or industrial floor scrubbers).

- Cost and manufacturability: Compared with high‑end rare‑earth magnets, ferrite provides a balance of magnetic strength and affordability, useful when many magnet segments are needed or when replacements may be frequent.

- Sufficient magnetic strength for many applications: For motors designed for moderate torque and continuous duty rather than maximal power density, ferrite magnets deliver reliable performance with stable flux output.

These characteristics have led to ferrite magnets being widely specified in cleaning equipment, exhaust fans, small‑scale motors, and commercial cleaning robots.

Practical Performance Records

Users and maintenance teams report several performance insights based on real-world use of ferrite‑magnet motors:

- Motors operating 6–9 hours per day in commercial cleaning devices show consistent rotational speed and torque stability over months of service.

- Instances of demagnetization under heavy thermal stress when magnets are used with appropriate coatings and are assembled under precision control.

- Devices with ferrite magnets tend to exhibit lower maintenance frequency compared with older motor designs — fewer bearing failures and less magnet replacement over time.

- For cleaning machines or floor scrubbers, the smoother torque output results in more uniform brush pressure, more consistent cleaning quality over extended runs.

Such feedback has encouraged more facility operators to specify ferrite‑magnet motors in their procurement criteria, valuing long‑term reliability and manageable maintenance over maximal power output.

Design and Manufacturing Considerations

When integrating permanent magnetic ferrite magnets into motor designs, manufacturers discuss several key parameters:

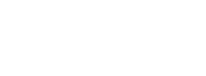

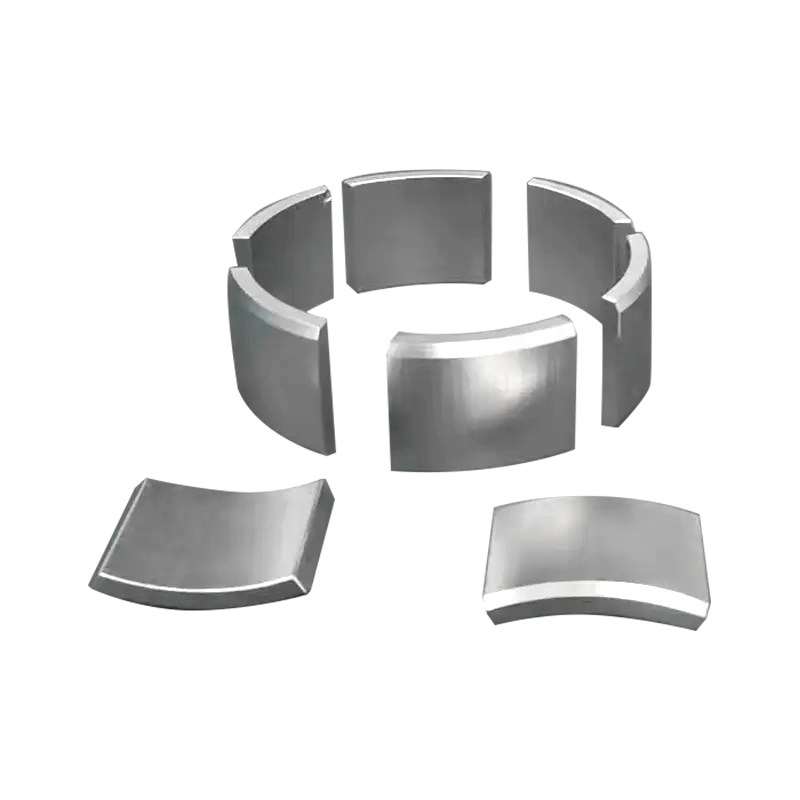

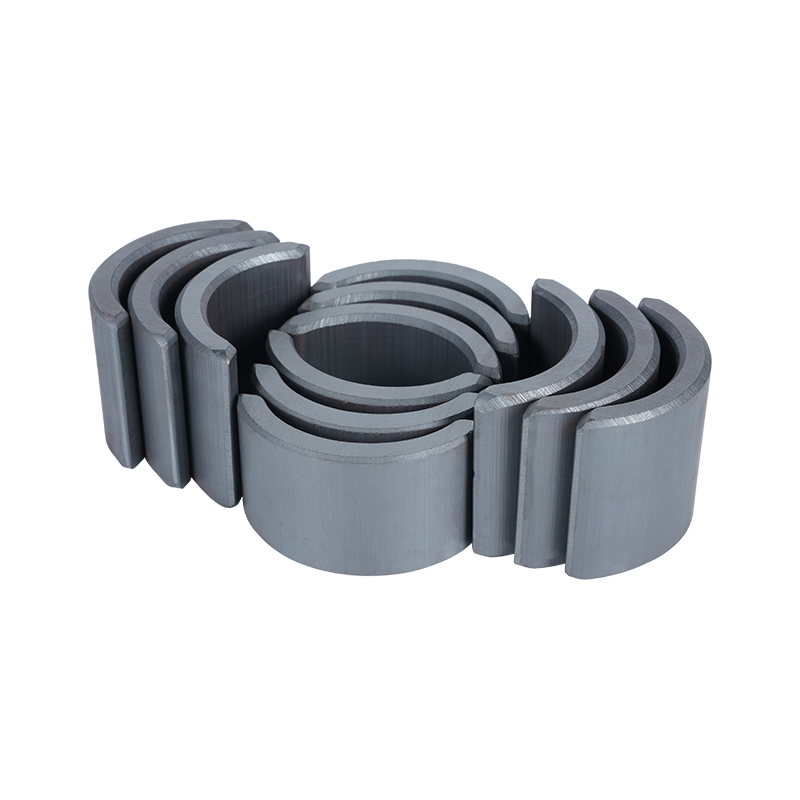

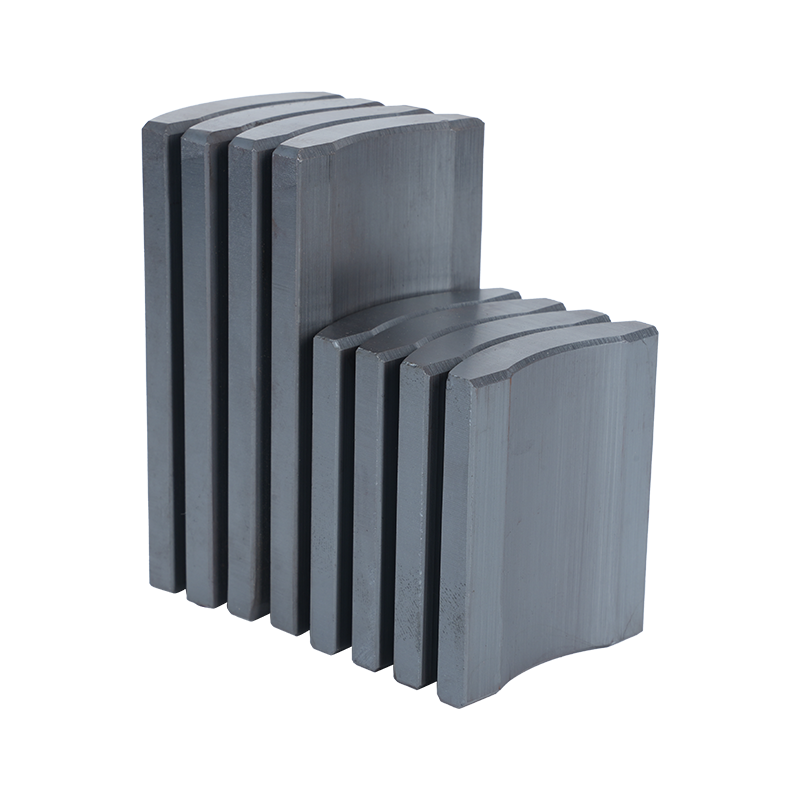

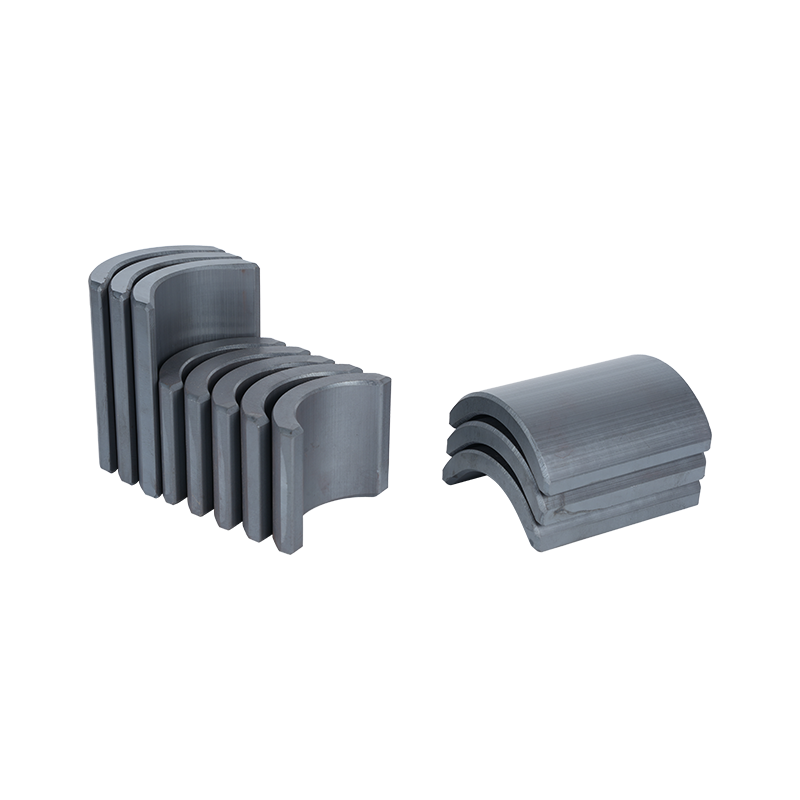

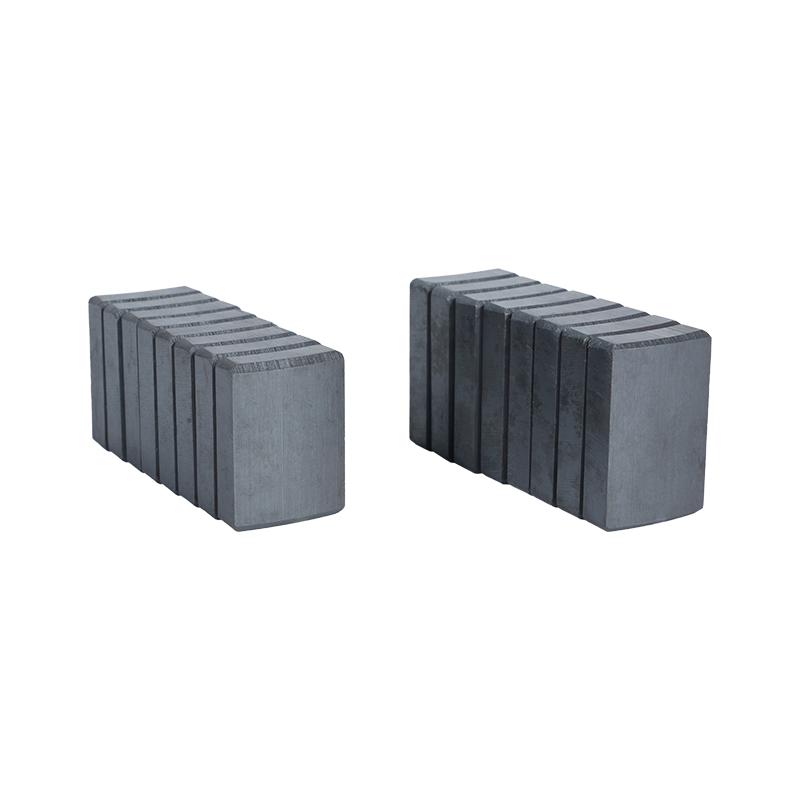

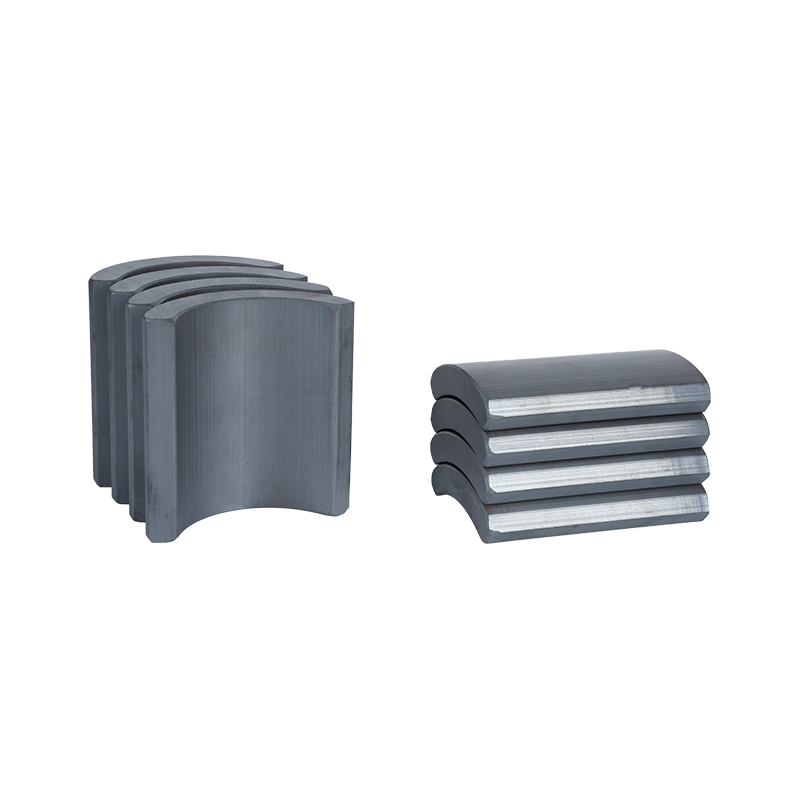

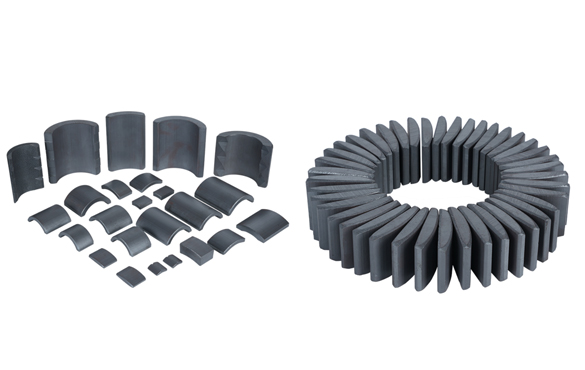

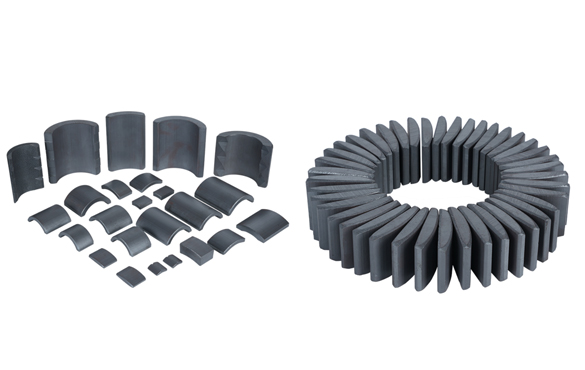

- Magnet geometry and placement — the size, shape, and orientation of each ferrite block or segment must align precisely to ensure balanced magnetic flux and avoid uneven rotor behavior.

- Coating and bonding — magnets used in machines exposed to dust, water, or cleaning chemicals require protective coatings and secure bonding to prevent corrosion or detachment.

- Thermal management — although ferrite is more thermally stable than many alternatives, designers still account for heat generation under heavy load, using venting, cooling, or heat-resistant housing materials.

- Spare part strategy — because ferrite is affordable and segmented magnets are easier to replace, many manufacturers maintain spare magnet kits, simplifying maintenance and reducing downtime.

These considerations help ensure that ferrite‑magnet motors remain dependable in demanding operational contexts, such as warehouses, hospitals, factories, or public facilities.

Use Cases

Several application areas currently rely heavily on ferrite‑magnet motors:

- Commercial floor cleaning machines — where consistent brush or roller motion and long service intervals are valuable.

- Ventilation and exhaust equipment — motors run for hours daily and benefit from magnetic stability and corrosion resistance.

- Small industrial devices and pumps — where cost and durability outweigh the need for torque density.

- Autonomous cleaning robots or compact machines — where weight, cost, and maintenance simplicity are key.

In summary, permanent magnetic ferrite remains a widely used and practical choice for motors in cleaning machines, ventilation units, and small industrial equipment.