Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

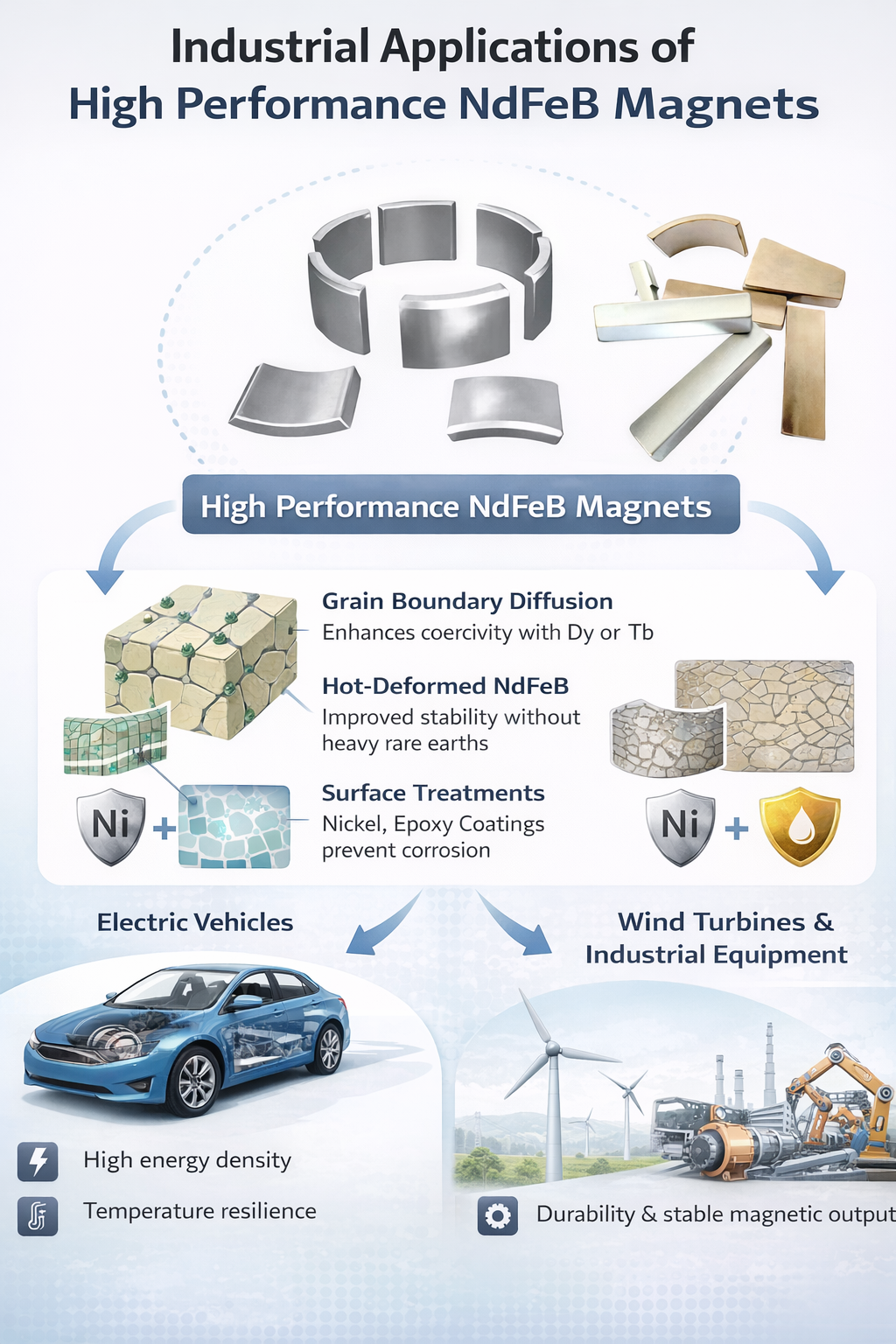

Industrial Applications of High Performance NdFeB Magnets

High Performance Neodymium-iron-boron magnets, commonly called High Performance NdFeB magnets, are now a regular part of many industrial products. One reason they are chosen so often is that they can create useful magnetic fields without taking up much space. Engineers use them in electric vehicle motors, wind turbine generators, and different kinds of factory machines. Because working conditions vary from one product to another, the magnets are adjusted during design and production to match those conditions.

In automotive work, especially for electric and hybrid cars, NdFeB magnets form a central part of the traction motors. These motors need magnets that give a reasonable level of energy density so that power can be delivered from a limited volume. Cars run at different speeds and experience changing temperatures, from cold starts to heavy loads on highways. The magnets therefore have to keep their magnetic strength through these normal operating changes. A method that is often used is grain boundary diffusion. Small amounts of dysprosium or terbium are added along the boundaries between crystal grains inside the magnet. This step raises the coercivity level, which means the magnet becomes more resistant to losing its field, and it does so without making the piece noticeably larger or heavier.

Temperature behaviour is another area that receives attention in car-related designs. Vehicles regularly go through heating and cooling as drivers move through traffic or park in different weather. Development efforts look at ways to change the alloy composition and control the internal grain structure. Such changes allow the magnets to handle many thermal cycles without losing performance. Hot-deformed NdFeB magnets are one outcome of this work. They show better resistance to temperature effects and higher coercivity, and they achieve this while using smaller quantities of certain earth materials that are harder to obtain.

When it comes to wind turbines and industrial machinery, the main requirements centre on steady operation over long periods. Wind generators are expected to turn for decades with little downtime, often in locations far from repair facilities. Factory equipment such as pumps, fans, and conveyor drives also runs continuously. Both types of systems expose the magnets to shifting temperatures, mechanical vibration, and sometimes damp air. The magnets must therefore avoid demagnetisation and deliver consistent output year after year. Hot deformation is again helpful here because it aligns the crystal grains in a way that adds mechanical strength and improves thermal properties. Careful control of the microstructure also contributes by producing a more even internal layout that copes better with daily stresses.

One drawback of NdFeB magnets is that they can corrode if moisture reaches the material. The iron in the alloy reacts with water and oxygen, forming rust over time. To prevent this, manufacturers add protective layers during production. Nickel plating is a frequent choice, sometimes combined with copper or other intermediate coatings. Epoxy resin coatings are also widely applied, particularly when parts will be used outdoors. These surface treatments act as barriers and help the magnets last longer in real conditions. Careful storage and correct installation further reduce the risk of early damage.

Overall, High Performance NdFeB magnets remain an important element in today's automotive, renewable energy, and general industrial equipment. Vehicle motors benefit from their energy density and ability to work across temperature ranges. Wind and heavy machinery designs rely on their long-term stability and resistance to daily wear. Continued work on diffusion methods, deformation processes, microstructure control, and surface protection keeps improving what these magnets can do.