Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Magnetic Tiles for Industrial Cleaning Motors

The term household appliances magnetic tiles is increasingly used within industrial cleaning applications, particularly in floor washing machine motors. These tiles, produced with ferrite magnetic materials, are engineered to meet the operational needs of commercial machines where long working cycles, consistent torque output, and reduced energy consumption are valued.

Understanding Magnetic Tiles in Cleaning Machines

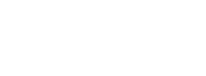

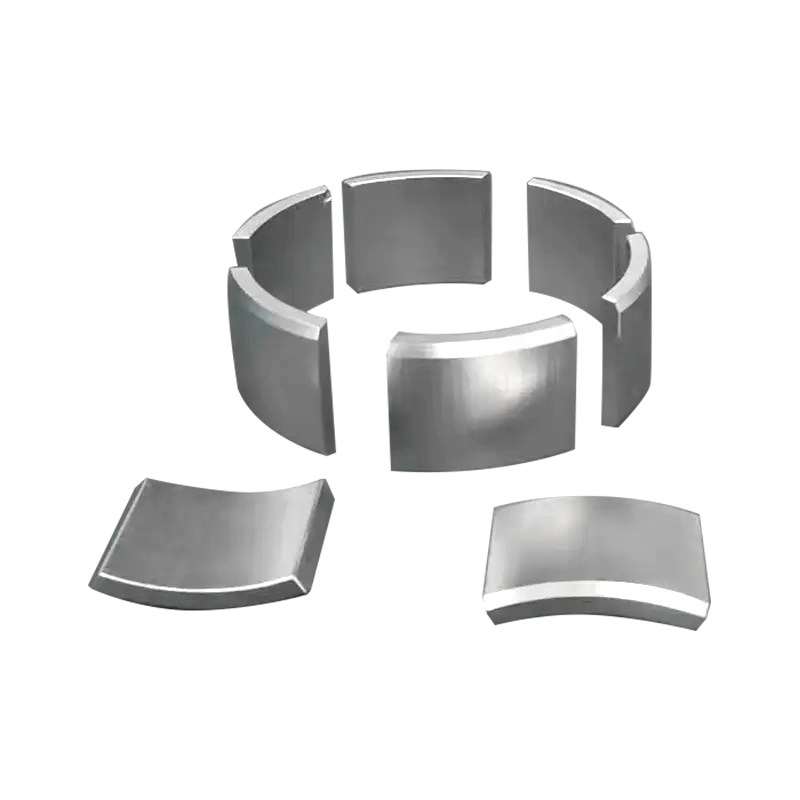

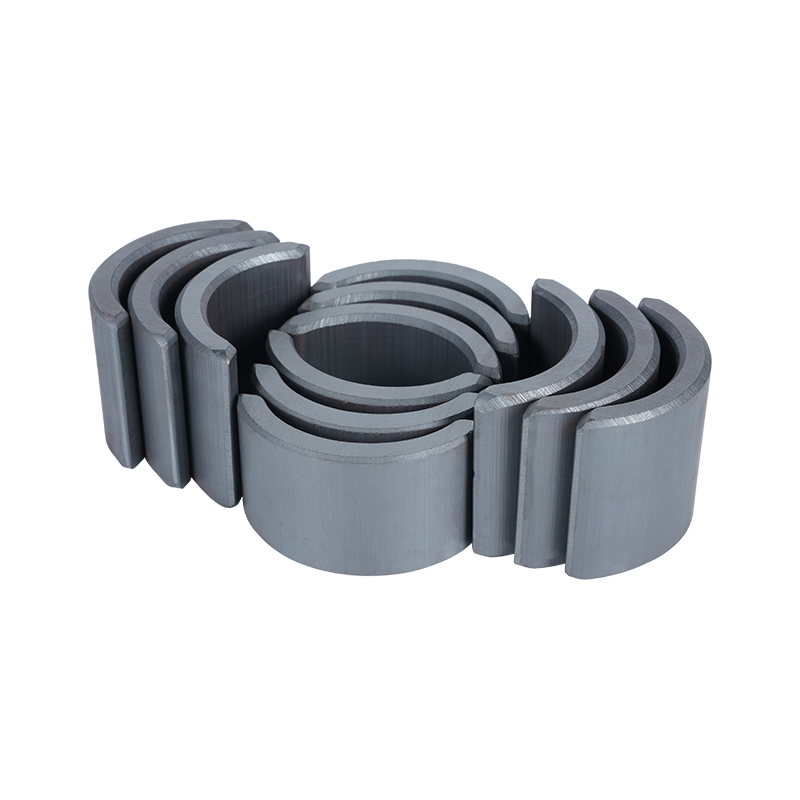

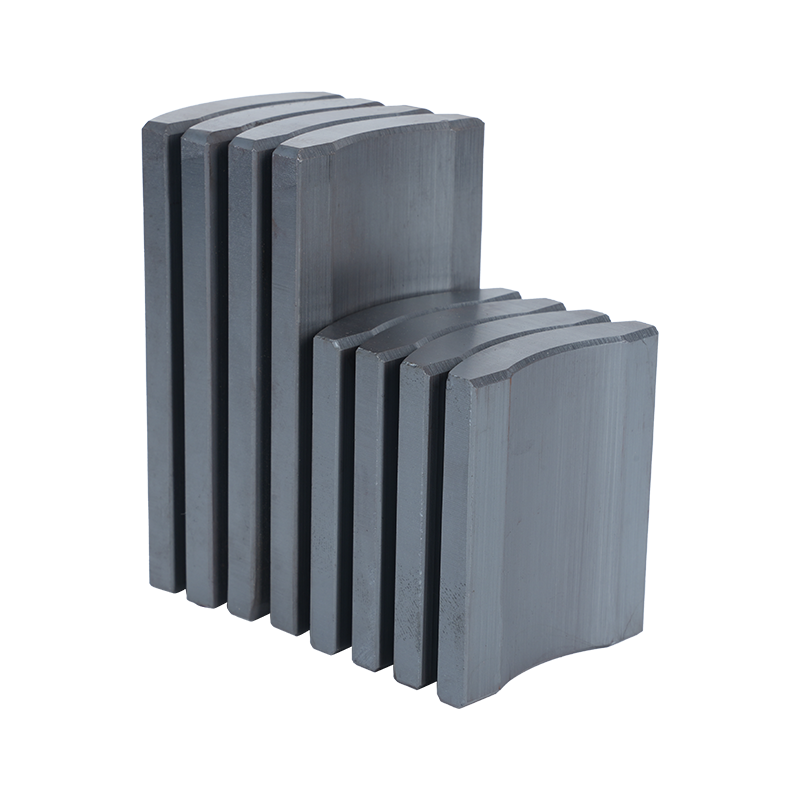

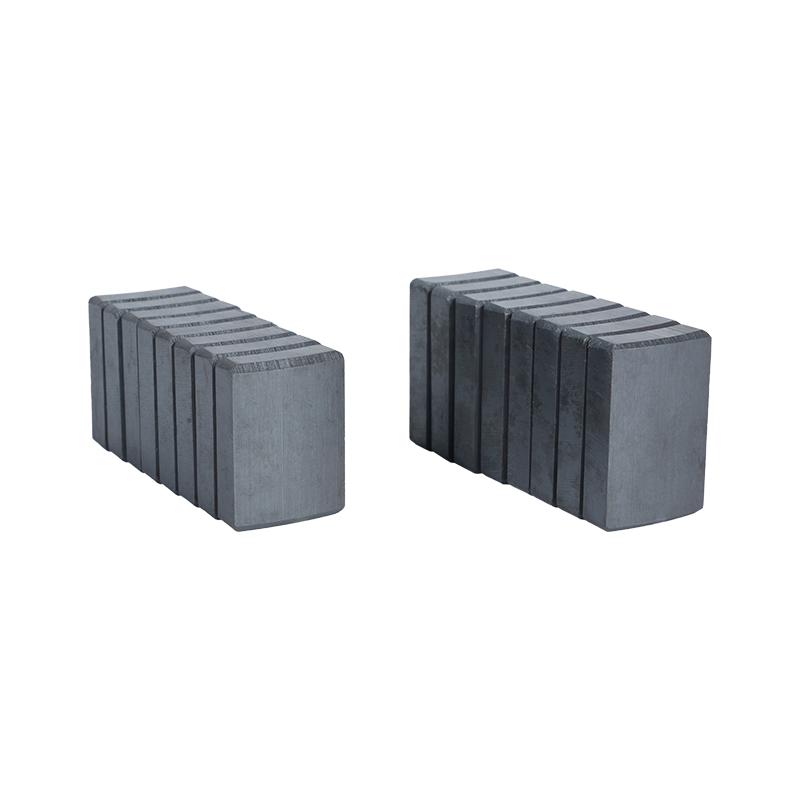

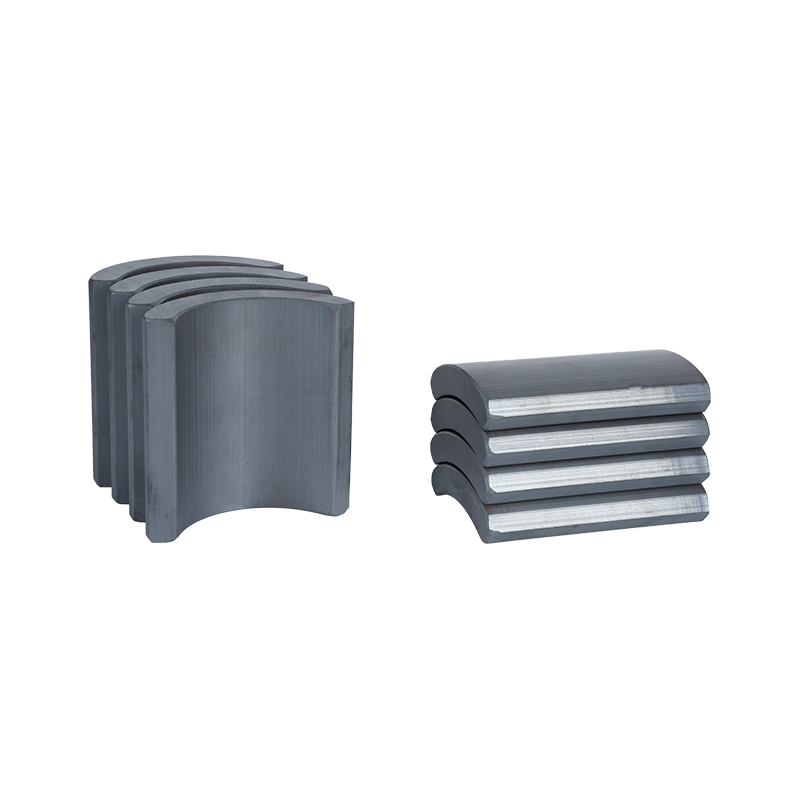

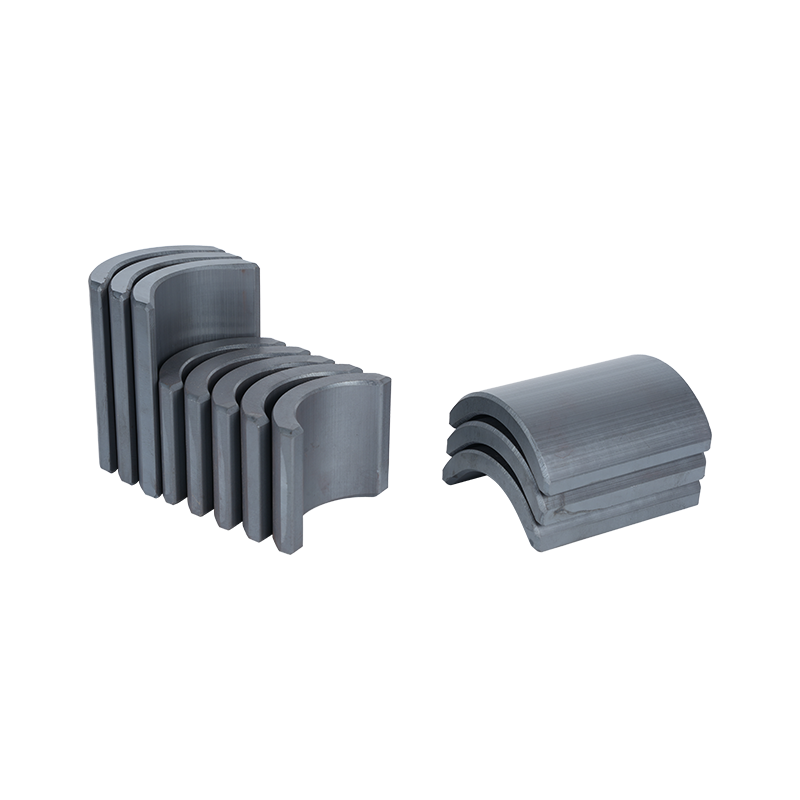

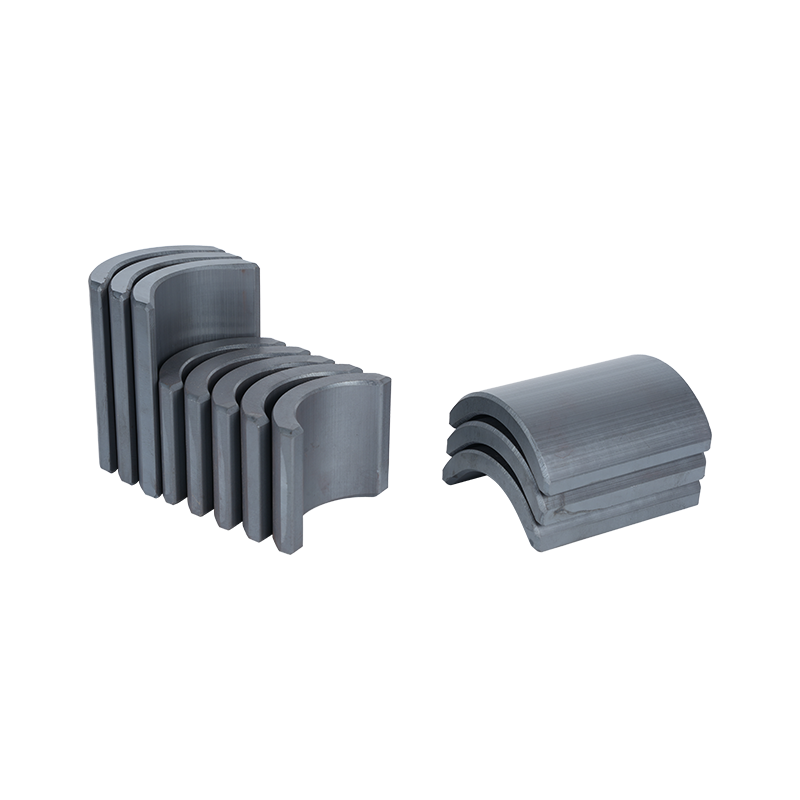

Magnetic tiles are shaped magnetic segments installed around the rotor of an electric motor. Their curved form enables uniform magnetic flux, stable rotational motion, and reduced vibration. In floor washing machines, this directly supports a smooth and consistent cleaning motion. These tiles are commonly manufactured using ferrite due to its balanced magnetic strength and thermal stability. Ferrite is known for resisting demagnetization under long operating hours, making it suitable for use in machines that run daily.

Focus on Durability and Stability

Industrial cleaning machines often operate in environments where temperature and continuous friction introduce heat. Magnetic tiles designed for this setting maintain their magnetic performance without excessive wear. Internal assessments indicate that ferrite segments maintain structural integrity over large working cycles. This long service capability contributes to predictable machine behavior and supports operators in environments such as schools, malls, logistics centers, and hospitals.

Motor Efficiency and Energy Performance

Magnetic tiles contribute to motor efficiency by sustaining a steady magnetic field. This regulated output decreases energy loss compared with unbalanced rotor structures. In commercial settings, machines using these tiles typically show reduced power draw over extended periods. This characteristic is helpful for battery-driven floor washing machines where runtime and charge conservation are important.

Additional insights show that ferrite motor segments help maintain torque consistency even when brush resistance changes. This balance reduces strain on internal components and limits unnecessary mechanical wear.

Useful Data Observed in Practical Application

- Floor cleaning machines using ferrite magnetic tiles maintain regular torque output across extended operating periods.

- The operational temperature range of ferrite tiles suited for cleaning machines remains stable under continuous duty cycles.

- When installed in machines operating 5 to 8 hours per day, segments do not show significant demagnetization effects.

- Structures based on tile-segmented motors demonstrate lower vibrational noise compared with non-segmented rotor constructions.

- Operators working on surfaces with variable friction observe steady rotation without sudden torque drops.

Production and Customization Characteristics

Magnetic tiles for cleaning machines are manufactured through sintering processes that allow reliable density and magnetic orientation. Many suppliers offer customization of tile arc dimensions, thickness, magnetization direction, and coating. These options allow machine manufacturers to design motors tailored to airflow needs, installation space, torque requirements, and cleaning brush sizes.

In addition, assembling tiles into segmented motors simplifies replacement procedures. Instead of replacing a full rotor block, manufacturers can service the machine by addressing an individual tile section. This approach reduces downtime and service cost.

Value Within Industrial Cleaning Equipment

Floor washing machines increasingly appear in environments where daily cleaning cycles are planned rather than occasional surface maintenance. The use of ferrite magnetic tiles supports this operational requirement by delivering:

- Predictable motion and torque control

- Reduced machine vibration

- Stable thermal and electromagnetic behavior

- Support for compact motor design

- Lower power usage over long work periods

Facility managers seeking reliable machinery often give attention to the internal motor structure. Machines incorporating these magnetic tiles represent a balanced form of strength, efficiency, and operational consistency suitable for general and specialized cleaning tasks.

In summary, the growing attention toward household appliances magnetic tiles in industrial motor assemblies reflects their importance in supporting floor washing machine performance, offering balanced efficiency, durability, and customizable engineering for a wide variety of commercial cleaning environments.