Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

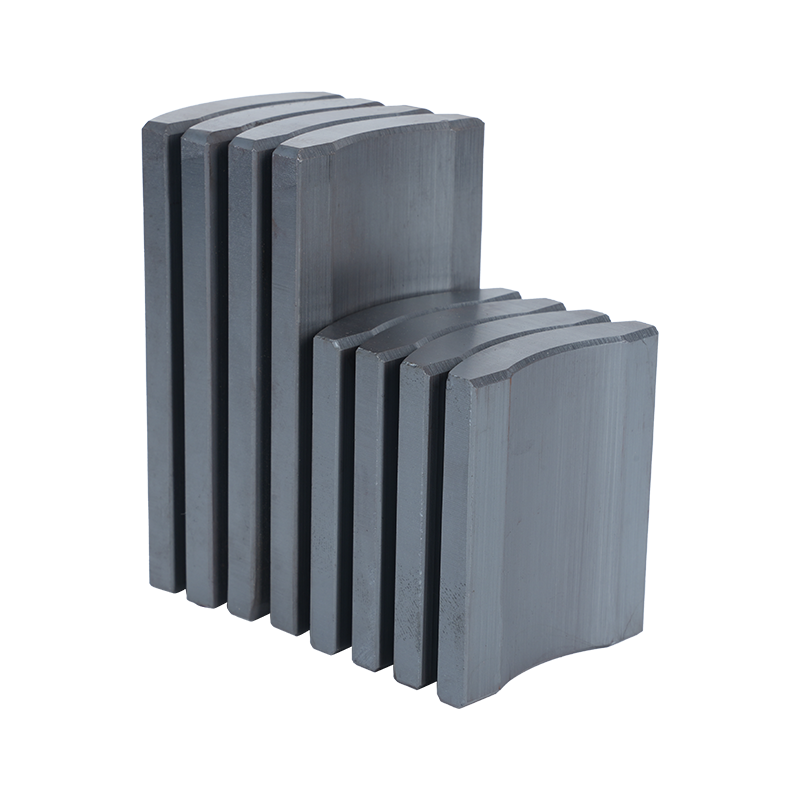

Motor Magnetic Tiles for Industrial Motors

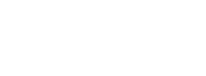

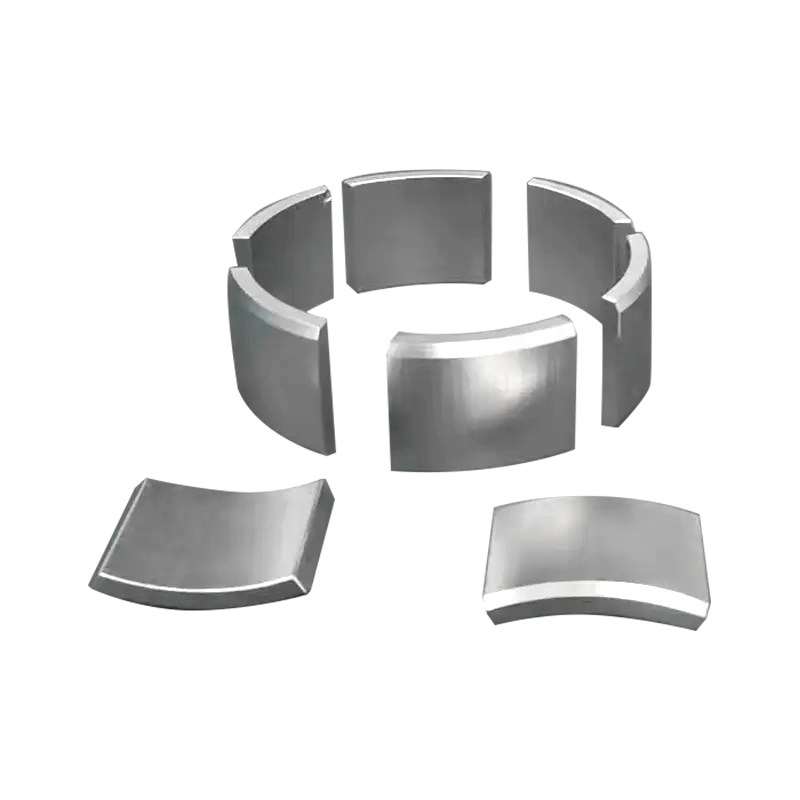

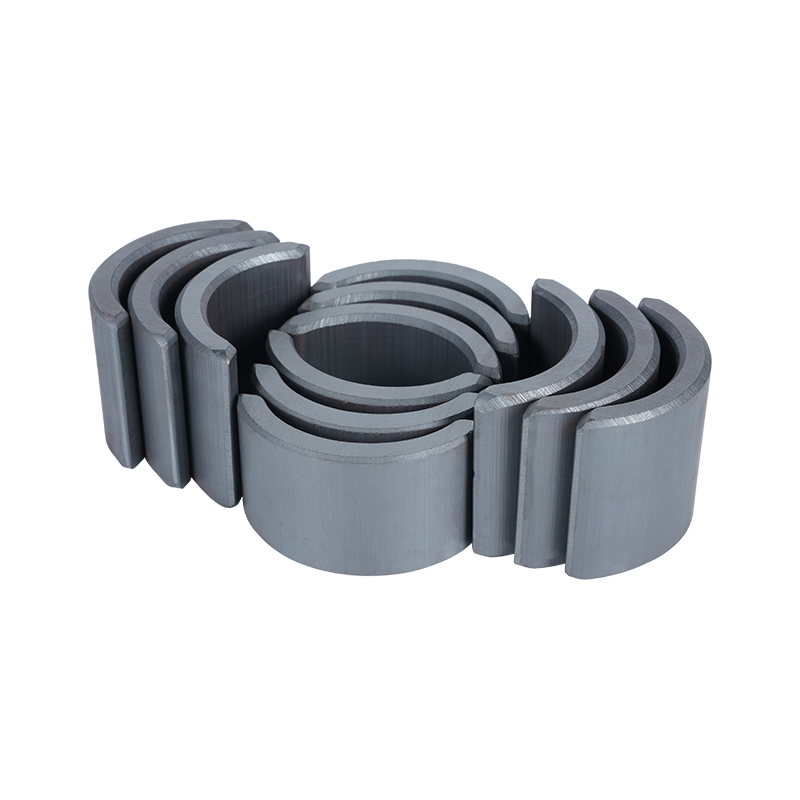

Motor magnetic tiles are specialized magnetic segments used in industrial and consumer-product motors. These components, often made from ferrite or rare-earth materials, are designed for integration into motors across automotive, household appliances, medical devices, cleaning machines, and other industrial applications. Their reliability and performance make them a key element in modern motor design.

Dongyang TianQi Motor Magnetic Tile Co., Ltd. specializes in producing high-quality magnetic tiles. The company operates large-scale manufacturing facilities with advanced equipment and an experienced R&D team. Their products serve a wide range of industries, providing magnetic solutions for automotive motors, treadmill motors, cleaning machines, household appliances, medical equipment, and magnetic transmissions.

Importance of Motor Magnetic Tiles

- Wide Industry Use: Magnetic tiles are applied in automotive motor systems, household appliance motors, medical devices, industrial cleaning equipment, and more. Their flexible design allows them to meet diverse operational requirements.

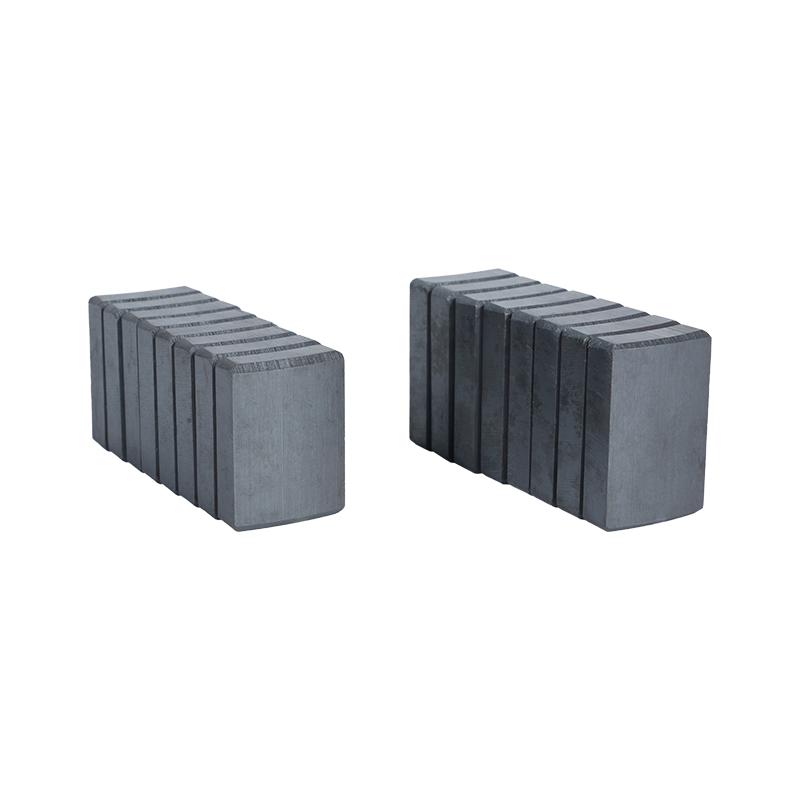

- Reliable Performance: Made from ferrite or NdFeB materials, the tiles provide stable magnetic flux, high coercivity, and resistance to demagnetization. These properties are essential for motors where consistent magnetic behavior affects torque, efficiency, and durability.

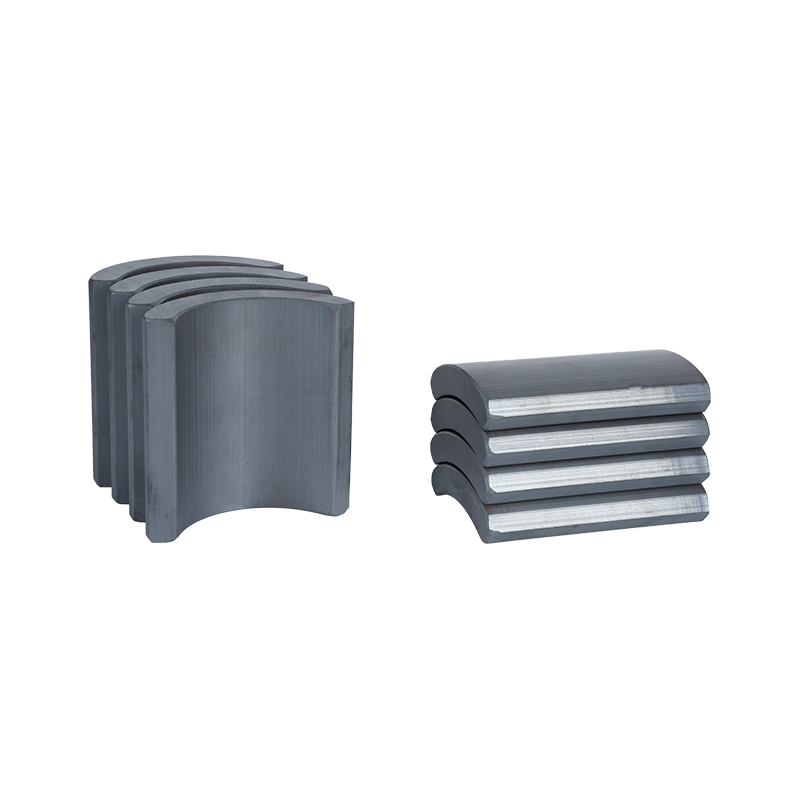

- Customization and Versatility: Magnetic tiles can be customized in shape, size, coating, and magnetic strength, enabling integration into various motor designs. This adaptability makes them suitable for different applications and motor configurations.

Typical Applications

Technical and Operational Advantages

Motor magnetic tiles improve motor efficiency by ensuring uniform magnetic flux and reducing energy loss. Their durable materials provide resistance to demagnetization, mechanical stress, and environmental wear. Modular shapes and coatings allow engineers to integrate them into compact consumer motors or larger industrial motors.

Benefits for Manufacturers

Manufacturers and engineers in multiple industries benefit from these magnetic tiles. Companies producing electric vehicles, home appliances, medical devices, fitness machines, or industrial machinery can enhance motor performance and reduce development time by using pre-designed magnetic tiles. Their ready-made design supports reliable operation while simplifying motor assembly.

Considerations for Integration

When incorporating motor magnetic tiles into industrial or consumer motor designs, careful planning and evaluation are essential to ensure good performance and durability.

1. Material Type and Magnetic Properties

The choice of material is a critical factor. Magnetic tiles can be made from ferrite, NdFeB, or other specialized magnetic materials, each offering different magnetic strength, temperature tolerance, and resistance to demagnetization. Using a material that does not align with operational demands may cause energy loss, reduced torque, or premature wear.

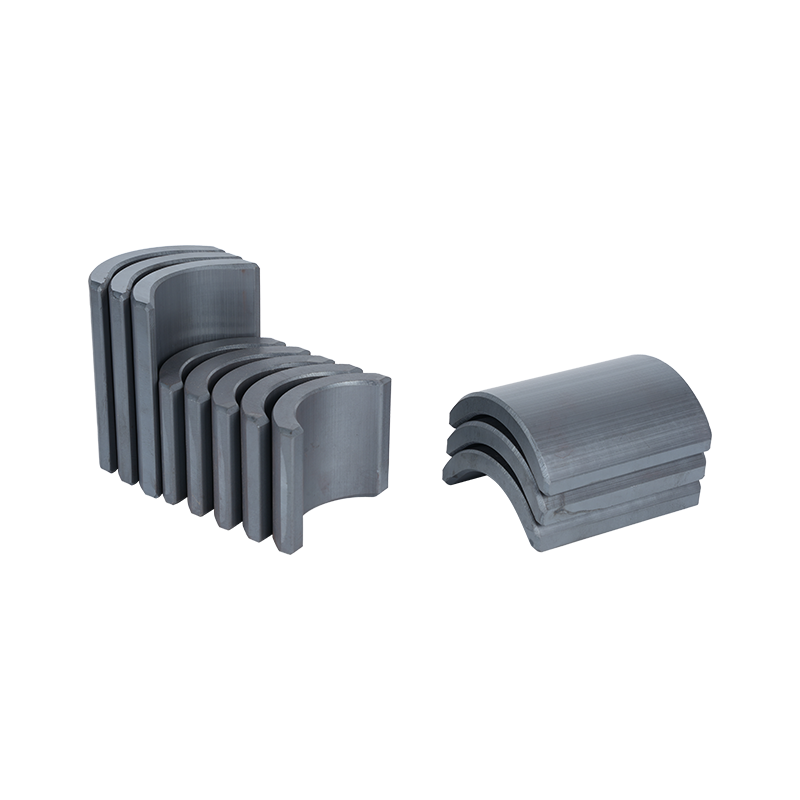

2. Dimensional and Geometric Specifications

Accurate sizing and geometric conformity are vital for proper assembly and alignment within the motor. Tiles must fit precisely within the rotor or stator, and their shape should be compatible with other motor components. Even slight deviations in thickness, arc angle, or curvature can affect magnetic performance and mechanical balance.

3. Environmental Factors

Magnetic tiles operate in a variety of conditions, including high temperatures, mechanical vibrations, and potentially corrosive environments. Temperature fluctuations can influence magnetic strength, while mechanical stress may cause structural damage or misalignment. Coatings or surface treatments may be required to prevent corrosion and enhance durability.

Conclusion

Motor magnetic tiles offer consistent performance and flexibility for a wide range of industrial and consumer motor applications. Their durable magnetic properties and customizable designs allow engineers to integrate them into motors for automotive systems, household appliances, medical devices, and industrial equipment, ensuring reliable operation under varied conditions.