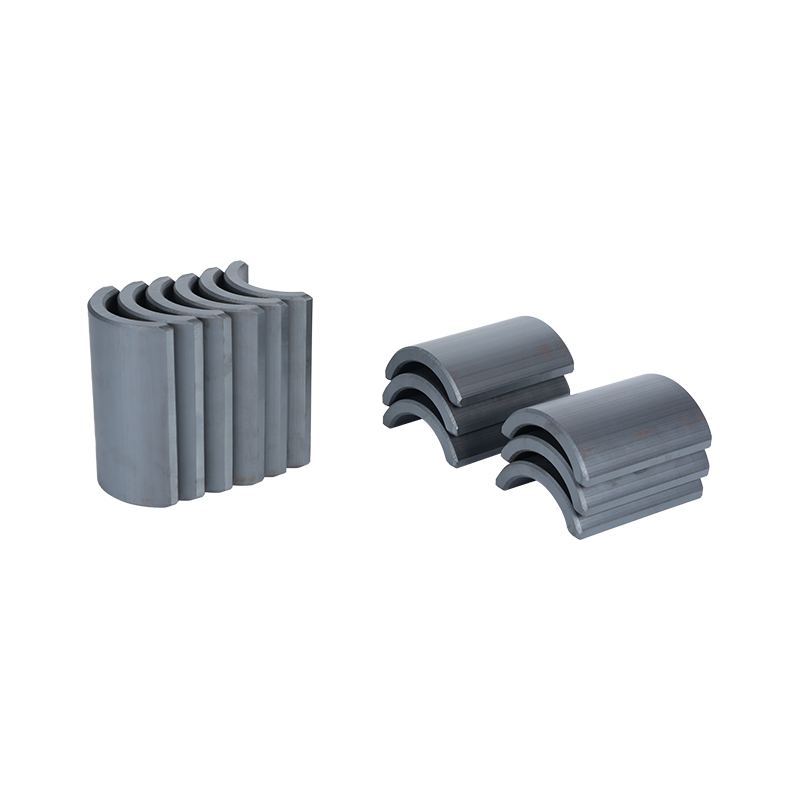

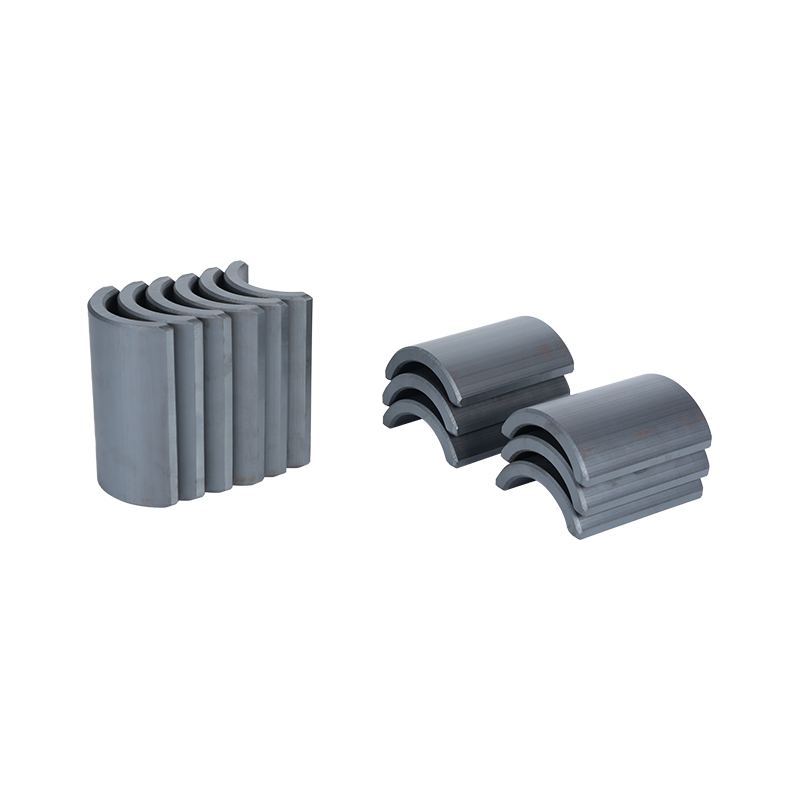

Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Car Magnetic Tiles: Enhancing Industrial Efficiency and Safety in Automotive Applications

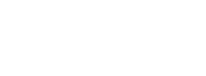

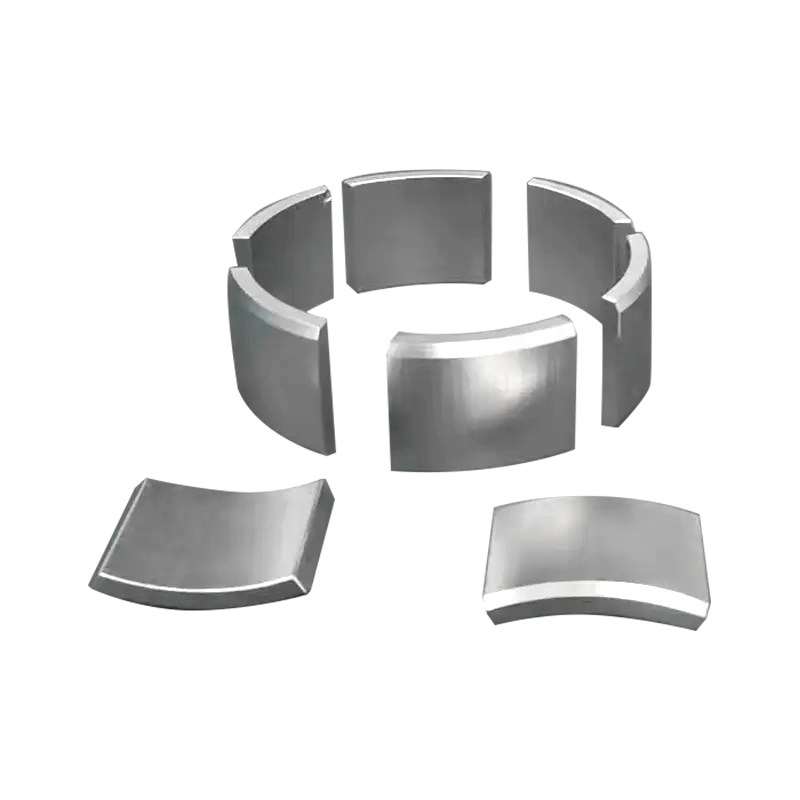

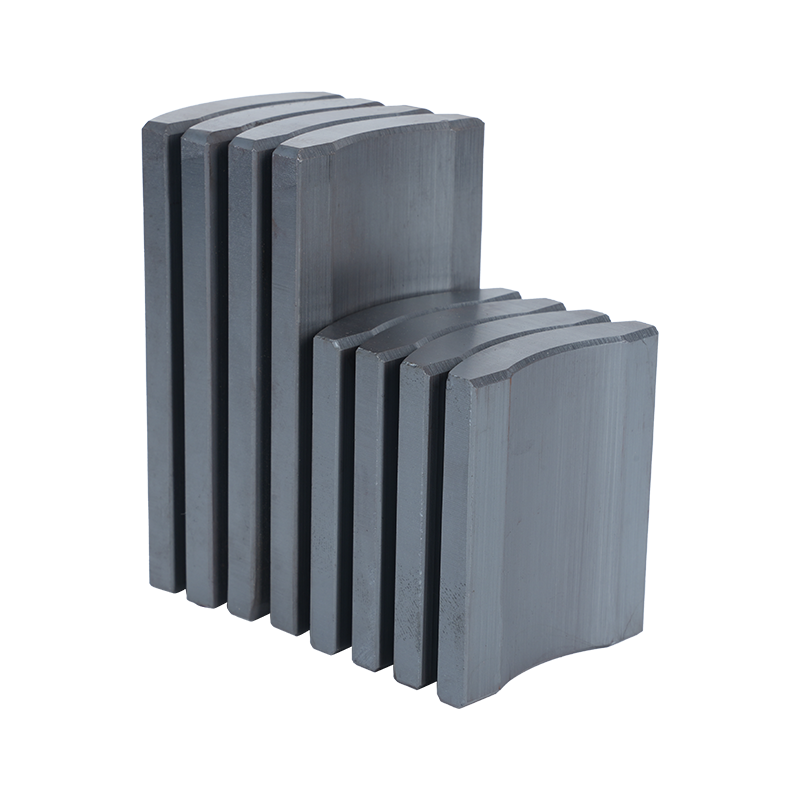

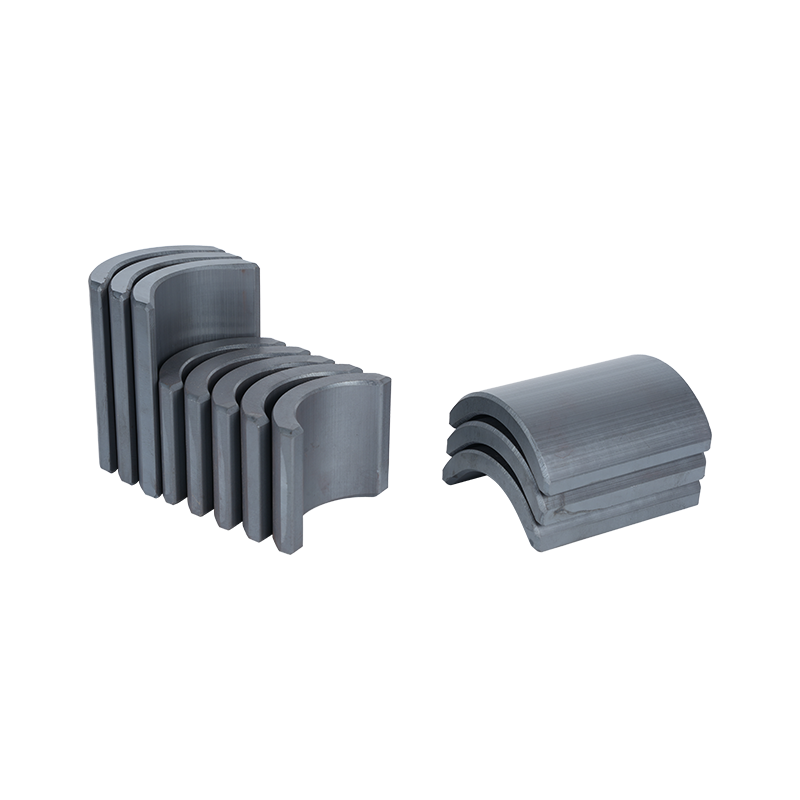

Car Magnetic Tiles are increasingly recognized as essential components in industrial automotive applications. These magnetic tiles provide reliable solutions for improving efficiency, safety, and precision in manufacturing, assembly, and maintenance processes. From large-scale production lines to specialized cleaning systems, car magnetic tiles help streamline operations while ensuring consistent performance.

Applications in Automotive Manufacturing and Assembly

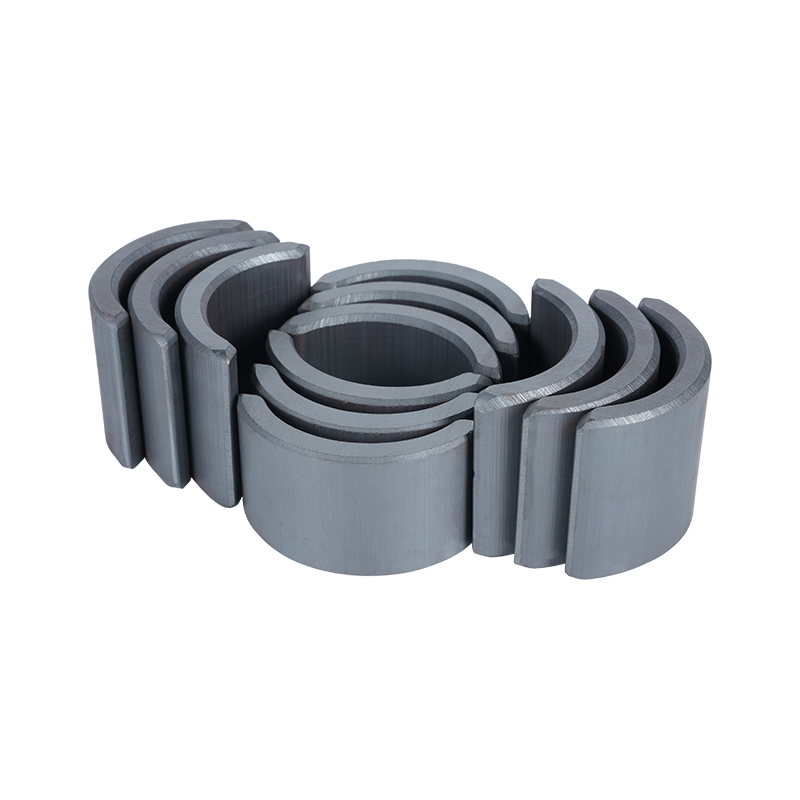

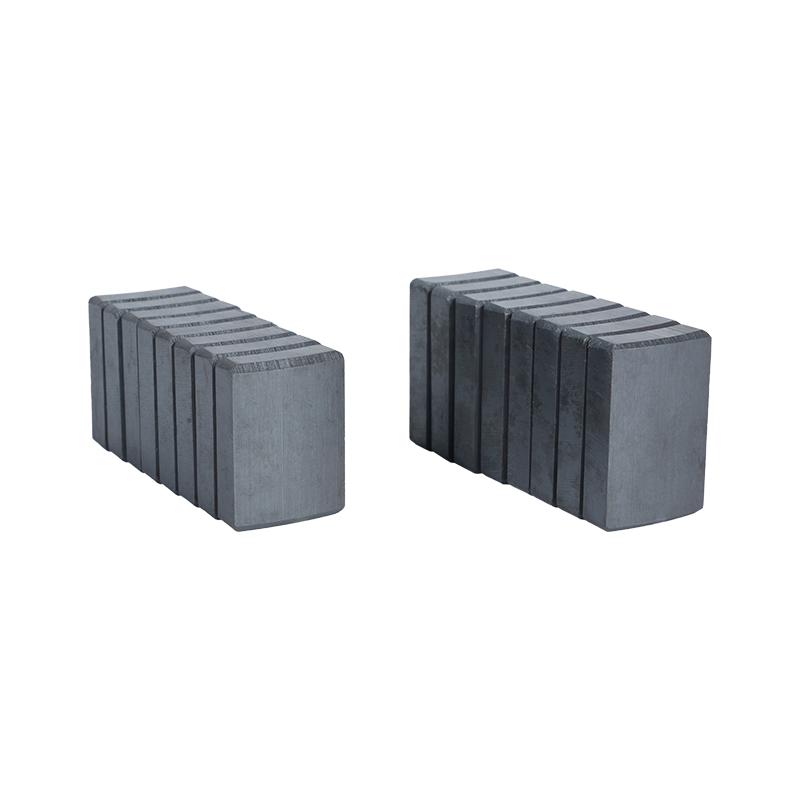

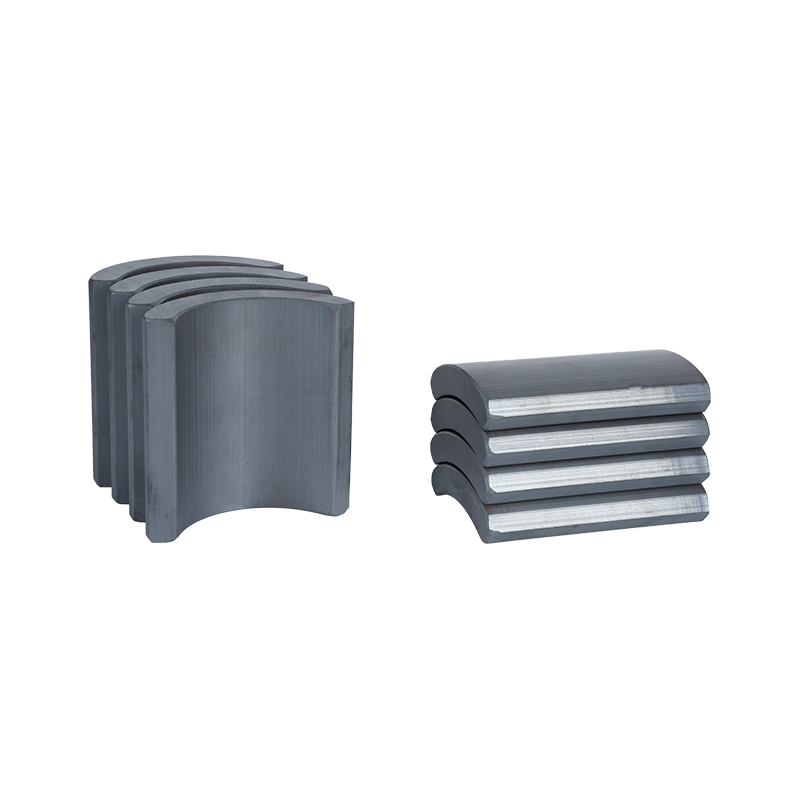

In automotive factories, car magnetic tiles are widely used in conveyor systems, robotic assembly lines, and automated tools. They serve as holding and positioning devices that stabilize car components during production. For example, magnetic tiles can secure metallic panels, engine parts, or chassis components in place, reducing errors and ensuring precise alignment. Their modular design allows quick replacement and adaptation to different assembly tasks, minimizing downtime and improving workflow efficiency.

Use in Automotive Cleaning and Maintenance

Car magnetic tiles play a significant role in industrial cleaning machines used for automotive parts. Magnetic tiles effectively attract metallic debris, such as metal shavings, dust, or filings, preventing damage to sensitive components. This functionality is particularly valuable in high-volume production lines where metal debris accumulation can disrupt operations or compromise product quality.

In addition, magnetic tiles simplify maintenance procedures. Their modular construction allows technicians to replace or reposition tiles quickly, avoiding long equipment shutdowns. This efficiency helps maintain continuous operation and reduces labor costs associated with routine cleaning and inspection tasks.

Performance Advantages in Industrial Settings

The durability and reliability of car magnetic tiles make them ideal for industrial applications. Ferrite or high-performance ceramic materials resist wear, corrosion, and high temperatures, ensuring long-lasting magnetic strength even under demanding conditions. Their strong magnetic properties provide consistent holding force, contributing to precise and stable operation of automotive tools and machinery.

Integrating magnetic tiles into industrial workflows improves operational efficiency. By securing parts, reducing material waste, and simplifying cleaning procedures, they reduce labor intensity and increase production precision. Industrial operators benefit from predictable performance and minimal downtime, which are critical in maintaining high output and quality standards.

Considerations for Industrial Implementation

Successful implementation of car magnetic tiles requires attention to several factors. Material compatibility is crucial, especially when interacting with sensitive metallic components. Environmental conditions such as temperature, vibration, and exposure to lubricants or cleaning agents must be considered to maintain magnetic performance. Proper installation, periodic inspection, and adherence to safety protocols ensure that magnetic tiles perform reliably throughout their service life.

Future Trends in Automotive Magnetic Tile Technology

Innovations in car magnetic tiles continue to enhance industrial applications. High-performance ferrite materials, modular designs, and improved magnetic alignment contribute to more flexible and efficient operations. Integration with IoT sensors and automated systems enables real-time monitoring of magnetic performance and equipment status, supporting predictive maintenance and further reducing downtime. These trends indicate a growing role for magnetic tiles in modern, automated automotive production lines.

Conclusion

Car Magnetic Tiles are transforming industrial automotive operations. Their applications in manufacturing, assembly, and maintenance provide reliable solutions for holding, positioning, and cleaning metallic components. Understanding the benefits and implementation considerations allows automotive facilities to optimize workflows, reduce operational costs, and maintain consistent quality. Magnetic tiles continue to support innovation and adaptability in modern automotive industries.