Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Motor Magnetic Tiles See Expanding Applications in Industrial and Automotive Fields

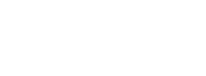

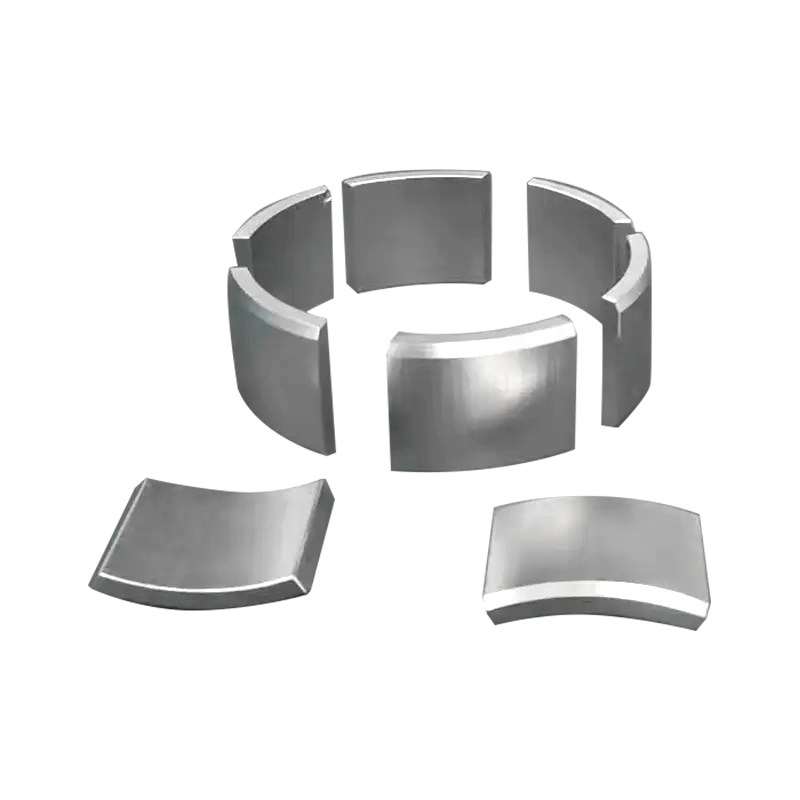

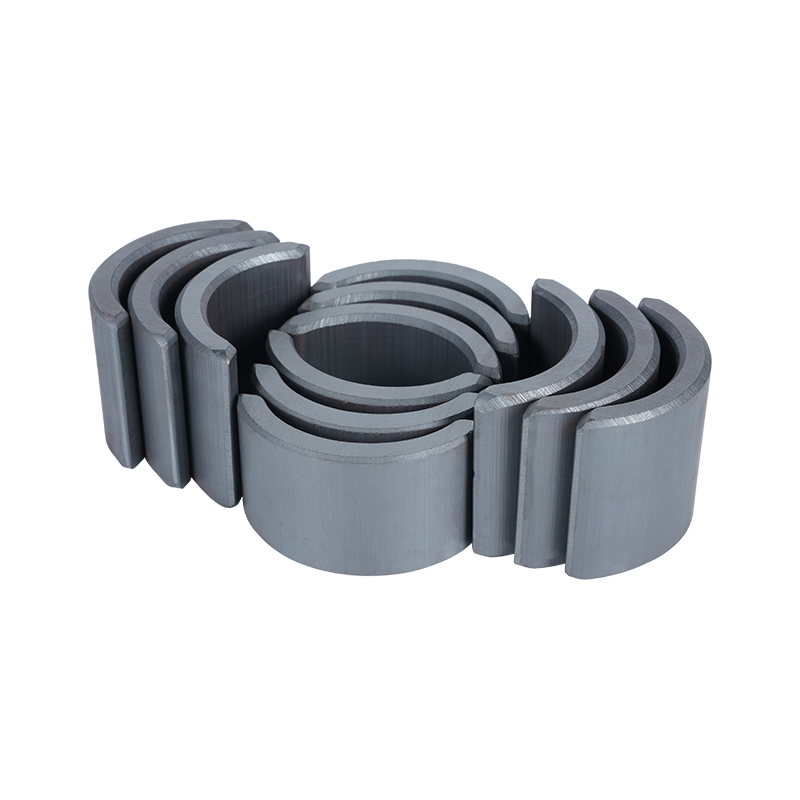

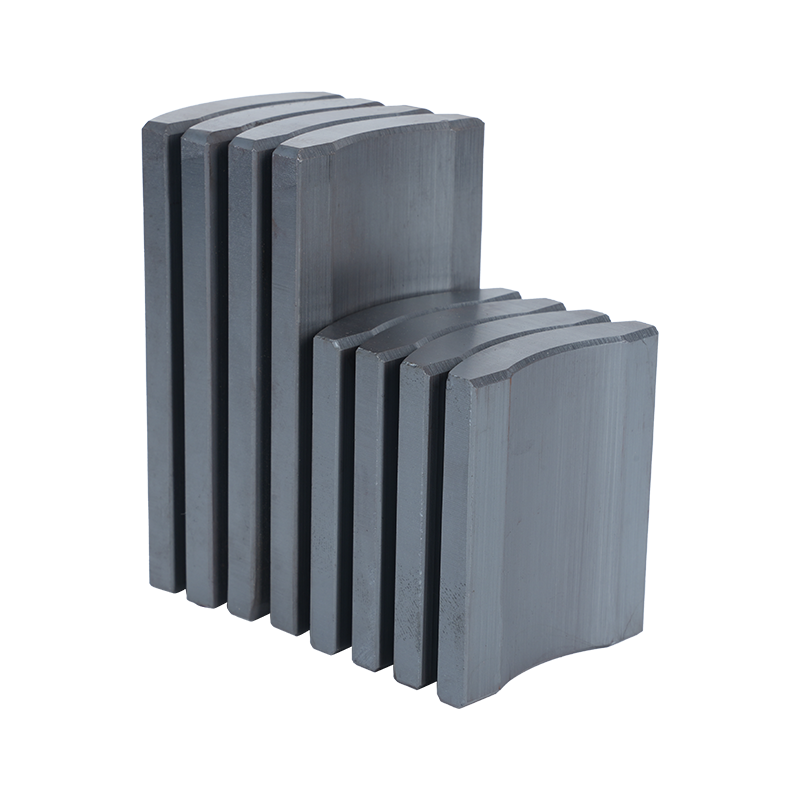

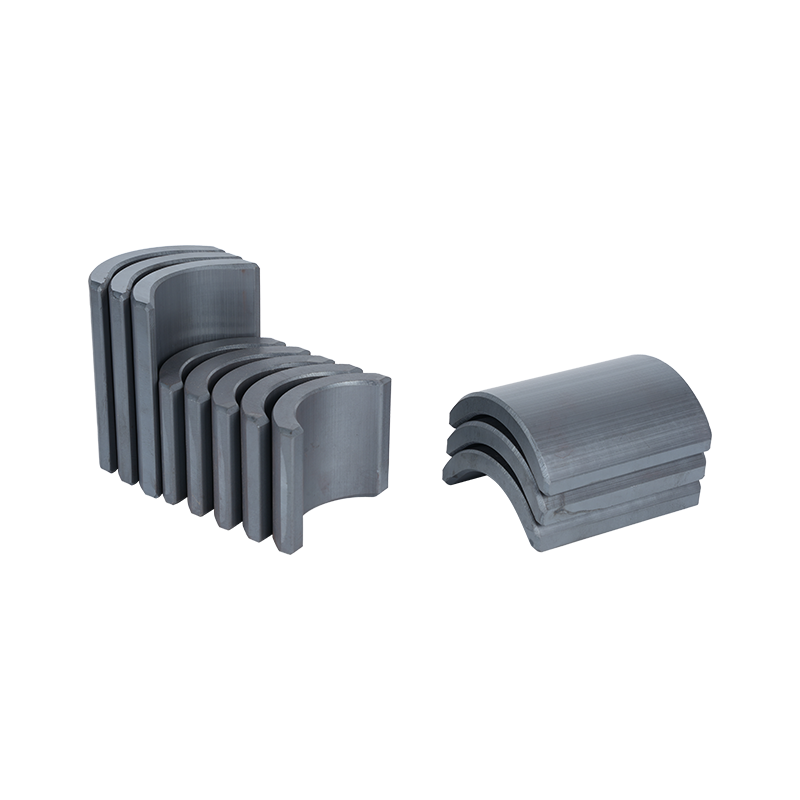

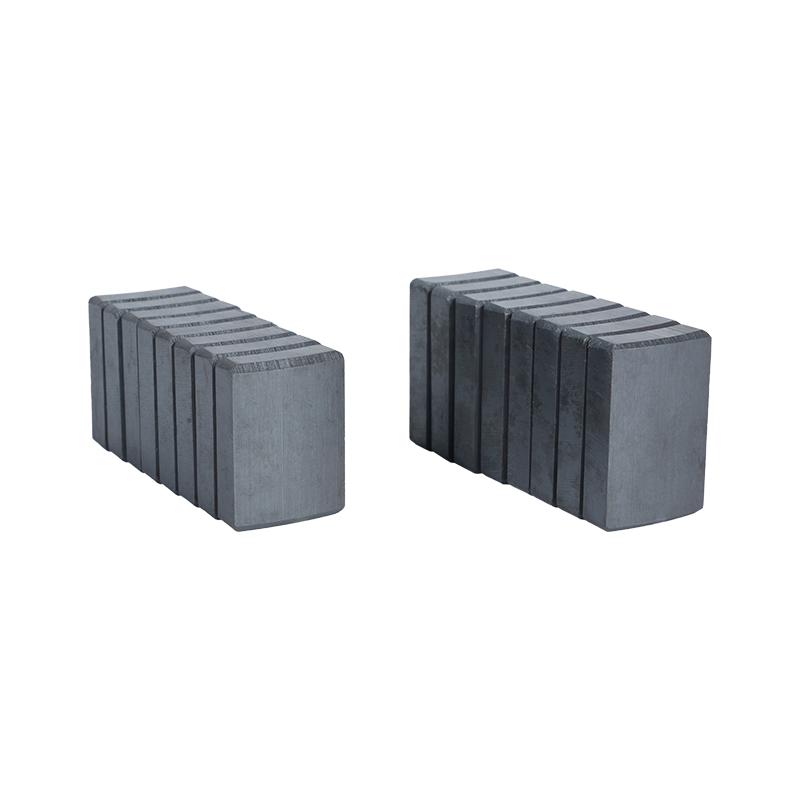

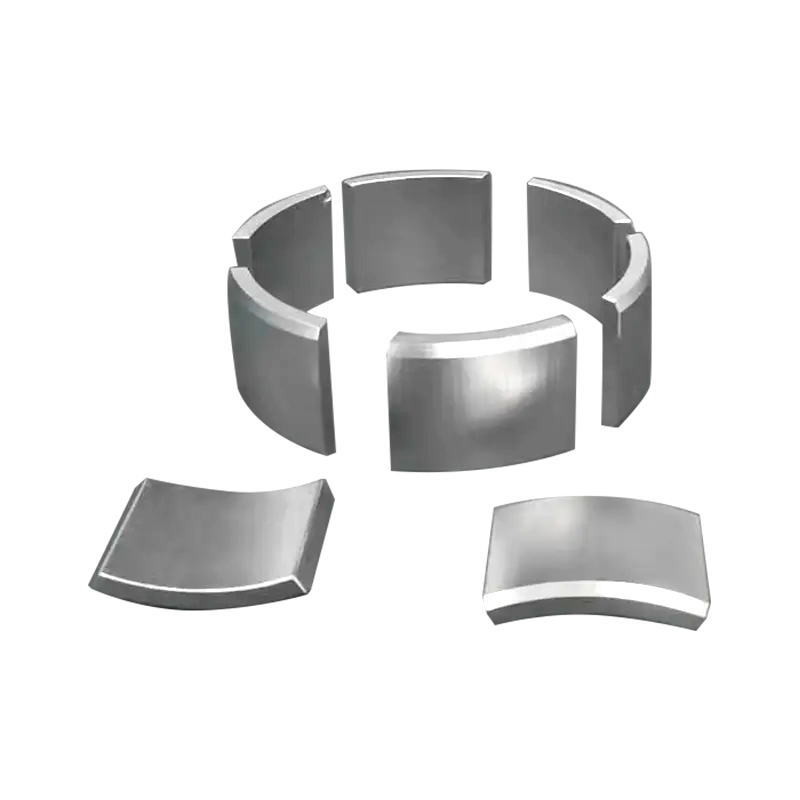

Motor magnetic tiles are gaining increased attention in various sectors due to their ability to enhance magnetic performance and support energy-efficient operations. These components, typically produced from ferrite or rare-earth magnetic materials, play an important role in electric motors, generators, and similar rotating machinery. Their use in automotive systems, industrial equipment, and renewable energy technologies has grown steadily as demand for reliable and adaptable magnetic solutions continues to rise.

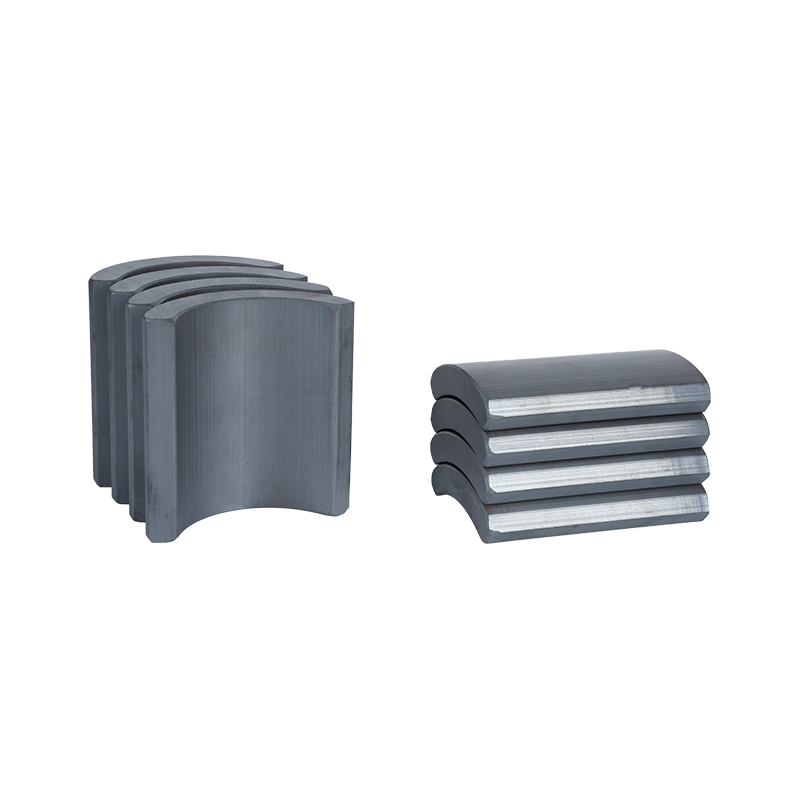

A primary function of motor magnetic tiles is to generate stable magnetic fields that enable efficient motor performance. By arranging tiles around the rotor or stator, manufacturers can optimize magnetic flux distribution and improve the overall operation of the motor. This design approach allows motors to maintain consistent torque and speed while minimizing energy loss, which is especially valuable in applications that require continuous or high-frequency operation.

One of the advantages of magnetic motor tiles lies in their flexibility during assembly. The tile-shaped segments can be configured in various patterns to meet different design requirements, accommodating both compact and larger motor sizes. This adaptability makes them suitable for a broad range of industries, including household appliances, electric vehicles, and industrial automation systems.

The automotive sector, in particular, has driven notable demand for motor magnetic tiles. Because electric and hybrid vehicles are becoming more common, the need for efficient and durable magnetic components has increased. Tiles used in traction motors and auxiliary systems contribute to reliable vehicle operation while supporting efforts to improve energy efficiency and reduce overall power consumption.

In renewable energy systems, such as wind and hydroelectric generators, motor magnetic tiles provide consistent performance under fluctuating loads. Their stable magnetic properties contribute to efficient energy conversion and long-term durability, which are essential for continuous power generation in demanding environments.

Manufacturing advancements have also improved the performance of magnetic motor tiles. Modern production techniques allow for precise control of tile composition and magnetization, resulting in uniform magnetic fields and predictable performance characteristics. Protective coatings and treatments are often applied to enhance resistance to corrosion and mechanical wear, extending the service life of these components in challenging operational settings.

Maintenance and handling considerations remain important when using motor magnetic tiles. Proper alignment during installation ensures balanced motor operation, while periodic inspections help identify wear or demagnetization over time. These practices contribute to reliable performance and reduce the likelihood of unexpected downtime in industrial and automotive applications.

The growing trend toward energy-efficient machinery and electrification in transportation suggests a continued role for motor magnetic tiles. Manufacturers are exploring ways to further refine their designs, including efforts to integrate tiles with advanced motor technologies such as axial flux and high-speed systems. These developments aim to balance cost, durability, and performance for an evolving market.

In summary, motor magnetic tiles have become a practical component for improving the efficiency and reliability of motors across various industries. Their adaptability, combined with steady advances in manufacturing and design, ensures ongoing relevance in applications ranging from consumer appliances to renewable energy projects. As electrification and efficiency remain central goals in modern engineering, motor magnetic tiles are expected to maintain their importance in supporting future technological growth.