Dong Yang TianQi Magnetic Segment Co.,Ltd.(formerly Shuangyang Magnet Tile) is a professional enterprise specializing in the production of motor magnet tiles

Search by posts

Categories

Popular products

Contact Us

Industry News

By Admin

By Admin

Inside a Magnetic Tiles Factory Serving Industrial Applications

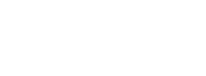

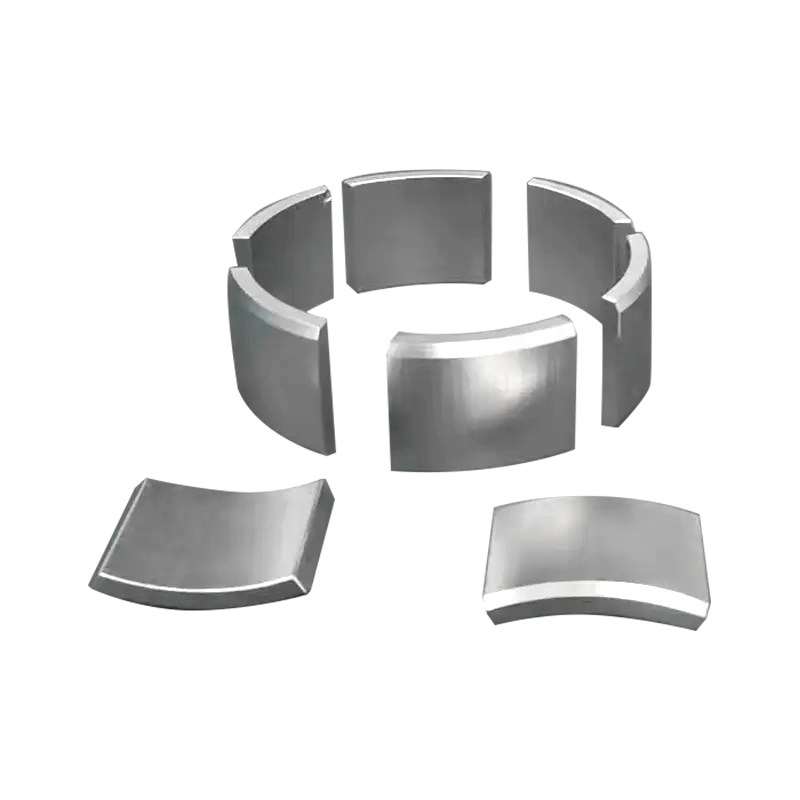

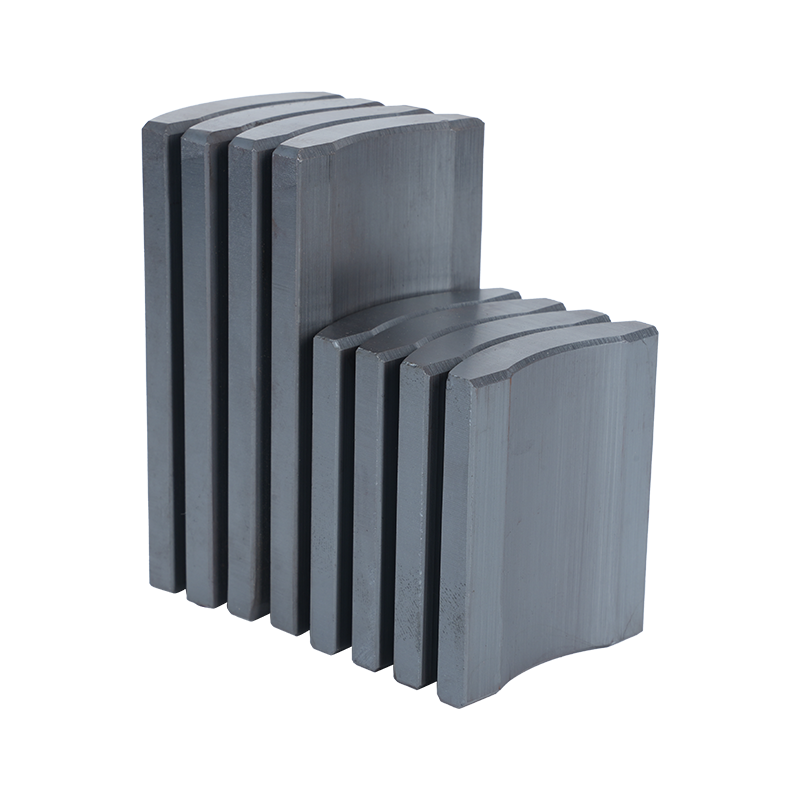

A modern magnetic tiles factory plays an important role in the supply chain of electric motors, household appliances, and industrial equipment. Unlike consumer products, industrial magnetic tiles—often referred to as magnetic segments or ferrite tiles—are core functional components. Their performance directly affects motor efficiency, energy consumption, and operational stability.

Three areas stand out in current factory operations: material consistency, precision manufacturing, and application-driven customization.

Material Control and Performance Stability

Industrial magnetic tiles are commonly produced from ferrite or rare-earth magnetic materials. These materials require strict formulation control during powder preparation, pressing, and sintering. Small deviations in composition or density can influence magnetic flux density, coercivity, and temperature resistance.

Industry testing data shows that magnetic performance deviation beyond five percent may reduce motor efficiency by more than three percent in certain applications. For this reason, factories invest heavily in raw material inspection and batch traceability. Incoming powders undergo chemical analysis and particle size evaluation before entering production.

Sintering remains one of the critical stages. Kiln temperature stability and atmosphere control determine final magnetic strength and structural integrity. Many magnetic tiles factories operate continuous kilns equipped with real-time monitoring systems to maintain uniform thermal conditions throughout each production cycle.

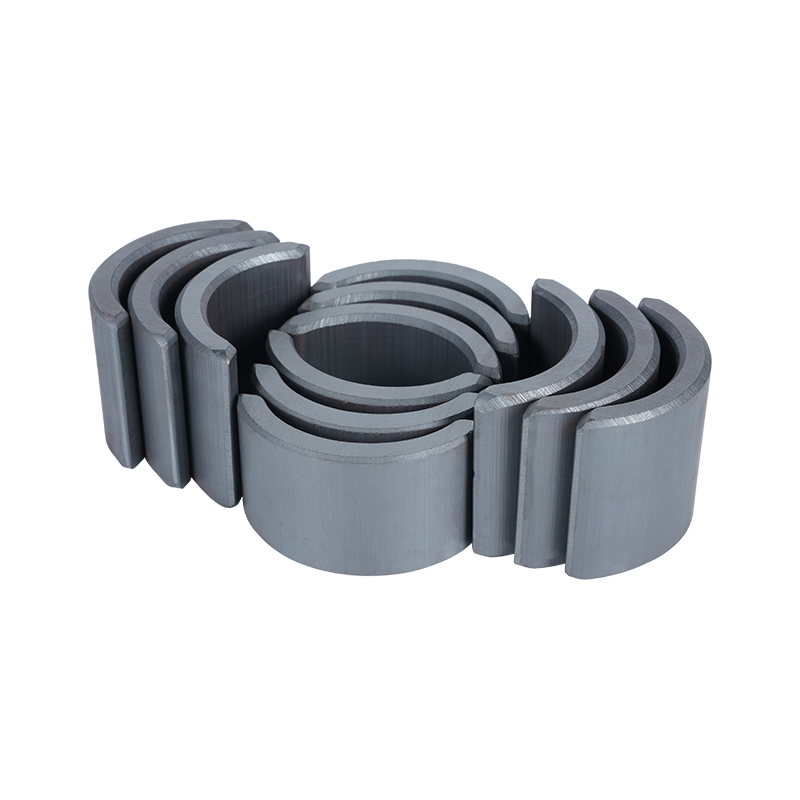

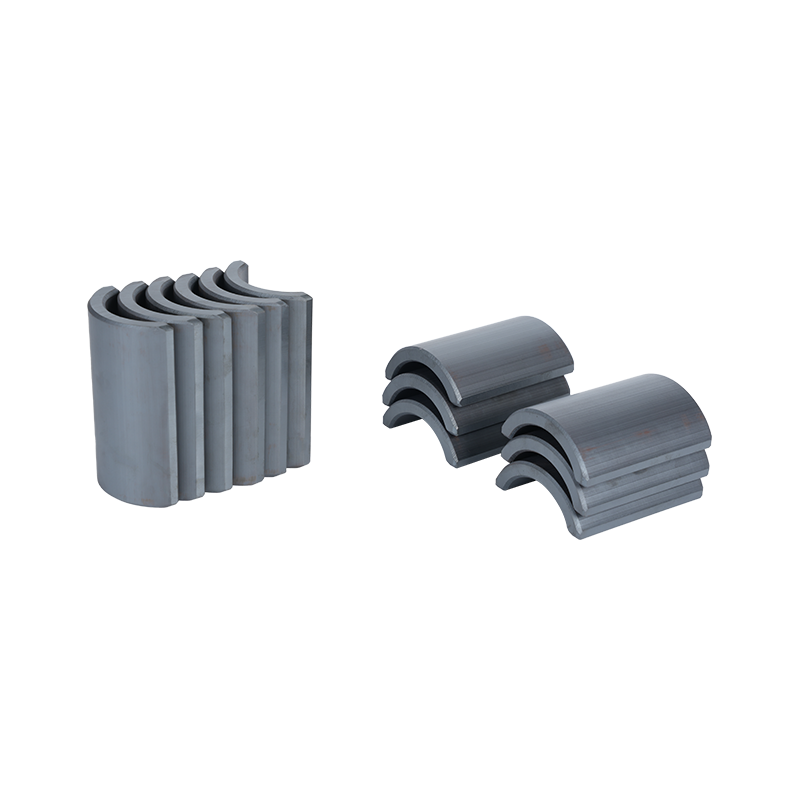

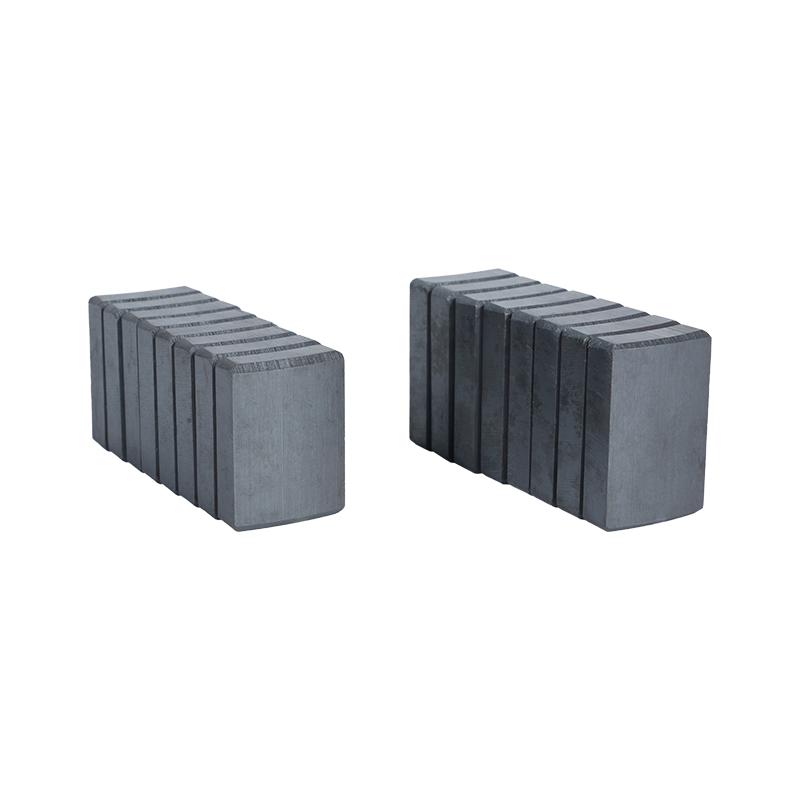

Precision Manufacturing and Dimensional Accuracy

Dimensional accuracy is another central topic in factory discussions. Industrial magnetic tiles must match strict tolerances to fit motor rotors or stators. Even minor dimensional variation can cause vibration, noise, or assembly failure.

Factories rely on high-pressure pressing molds and CNC grinding to achieve consistent geometry. Automated inspection systems measure thickness, arc angle, and surface flatness at multiple points. Statistical process control data from established manufacturers indicates that dimensional tolerance is often controlled within ±0.02 mm for standard motor applications.

Surface finishing also matters. Smooth surfaces improve bonding performance during assembly, especially when magnetic tiles are fixed using adhesives or resin systems. As a result, polishing and surface treatment steps receive increasing attention during final inspection.

Customization for Industrial and Appliance Use

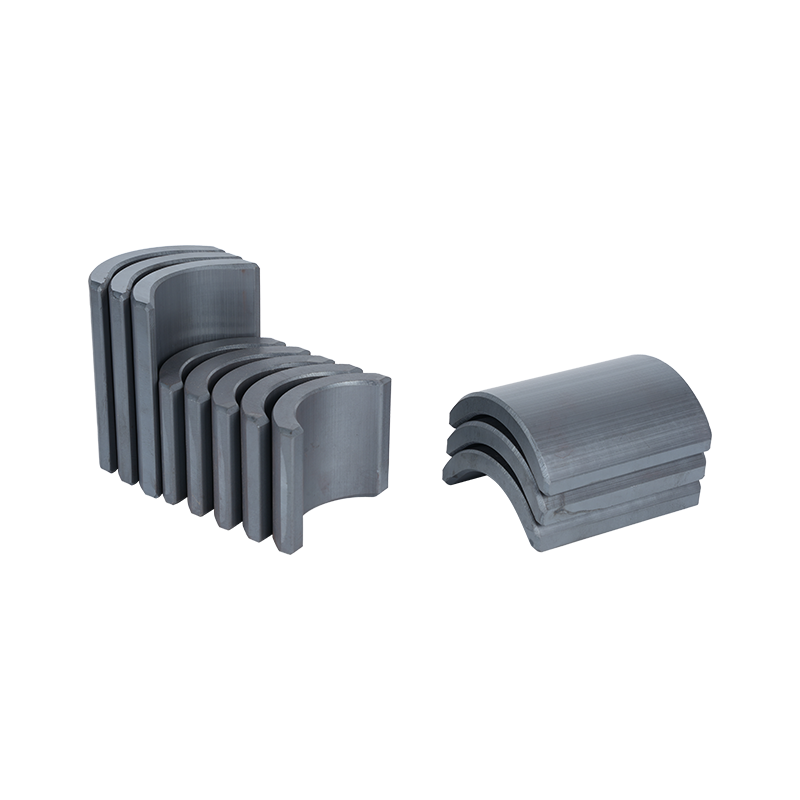

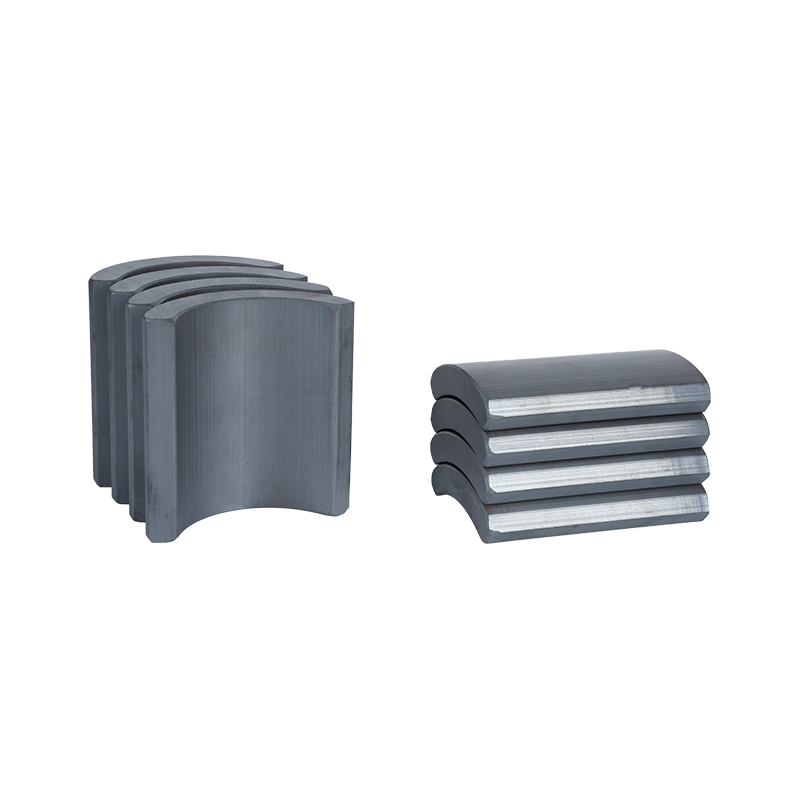

Customization demand continues to shape the structure of a magnetic tiles factory. Manufacturers of electric motors, compressors, fans, and generators often require specific arc shapes, magnetization directions, or performance grades.

Industrial procurement data suggests that customized magnetic tiles account for over half of total factory output in export-oriented facilities. Instead of producing large volumes of identical parts, factories manage multiple small-to-medium batch orders tailored to specific equipment models.

Engineering teams use magnetic simulation software to adjust magnet geometry and performance parameters before tooling begins. This reduces development cycles and limits trial-and-error costs. Typical time from design confirmation to pilot production ranges from four to eight weeks, depending on complexity.

Factory Operations and Compliance Requirements

Daily operations inside a magnetic tiles factory combine automation and skilled labor. Pressing, sintering, and grinding processes are largely automated, while magnetization, inspection, and packaging involve trained technicians. Final inspection includes magnetic performance testing, dimensional checks, and visual examination.

Compliance has become a routine part of factory management. Many buyers request documentation related to ISO 9001 systems, material data sheets, and performance test reports. Traceability records help link finished products to specific production batches, supporting long-term supply stability.

FAQ

What are industrial magnetic tiles mainly used for?

They are widely used in electric motors, household appliances, compressors, fans, and industrial machinery.

Which materials are common in magnetic tile production?

Ferrite materials are common, while some applications require rare-earth magnetic compounds.

How do factories ensure magnetic performance consistency?

Through strict raw material control, controlled sintering processes, and batch-level magnetic testing.

Can magnetic tiles be customized for specific equipment?

Yes. Shape, size, magnetization direction, and performance grade are commonly customized.